Concrete is one of the most widely used building materials, but to truly unlock its strength and durability, proper reinforcement is essential. Two common methods are wire mesh and fiber mesh reinforcement. While they serve a similar purpose—enhancing concrete performance—they differ significantly in structure, application, cost, and effectiveness.

In this comprehensive guide, we’ll compare wire mesh and fiber mesh in detail, helping you make the best choice for your concrete project.

Table of Contents

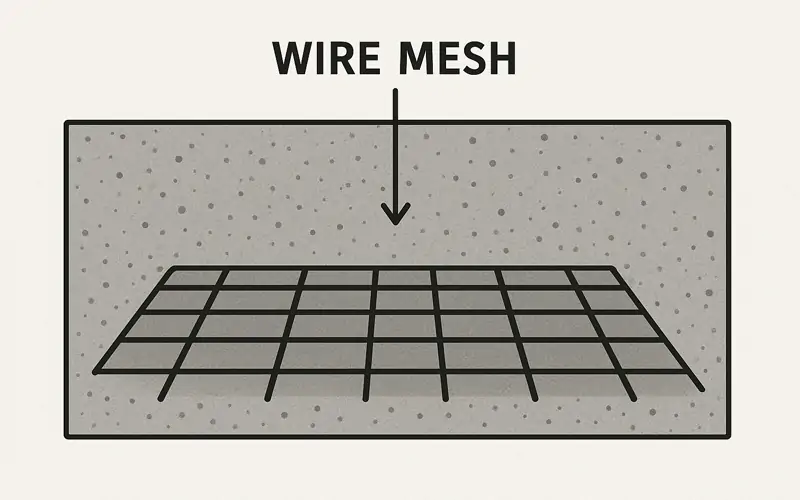

ToggleWhat is Wire Mesh in Concrete?

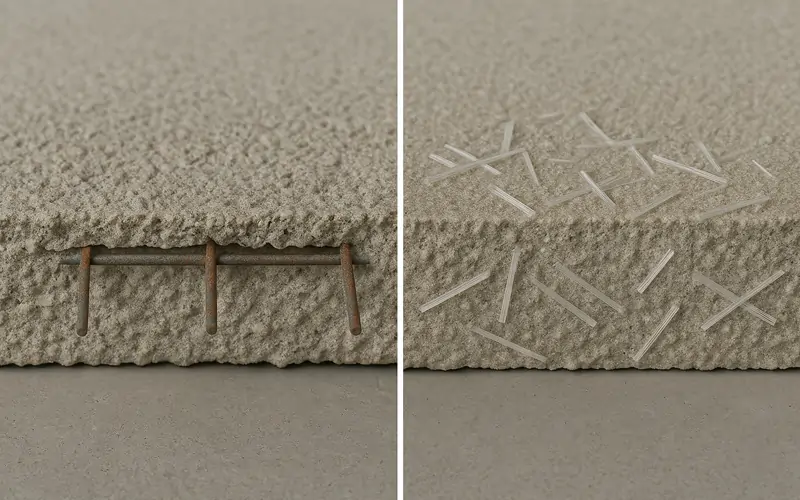

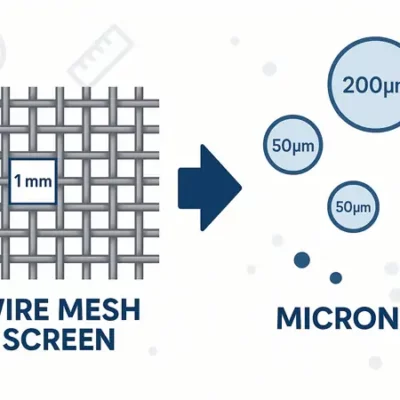

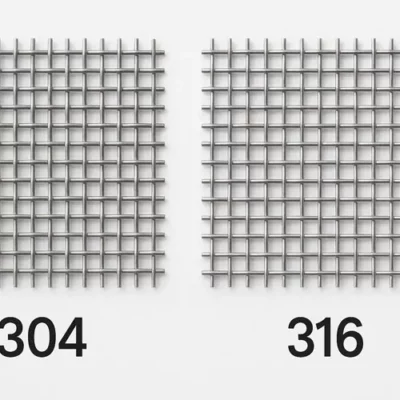

Wire mesh, often referred to as welded wire reinforcement (WWR), is a grid of steel wires arranged in perpendicular patterns and welded at the intersections. It typically comes in sheets or rolls, making it a go-to solution for reinforcing concrete slabs and structures.

How Wire Mesh Reinforces Concrete

Wire mesh provides structural support by holding concrete together under tensile stress. It helps distribute loads, reduces the risk of large cracks, and enhances overall durability—especially in flatwork like driveways, sidewalks, and industrial floors.

Common Applications of Wire Mesh

-

Commercial & industrial floors

-

Concrete pavements & roadways

-

Retaining walls & precast panels

-

Large slabs with heavy load requirements

Pros of Wire Mesh

-

Strong structural reinforcement

-

Ideal for large, high-load applications

-

Complies with most building codes

-

Long-term durability when properly installed

Cons of Wire Mesh

-

Labor-intensive installation (requires chairs & proper placement)

-

Susceptible to rust if not coated or improperly embedded

-

Heavier handling and transport costs

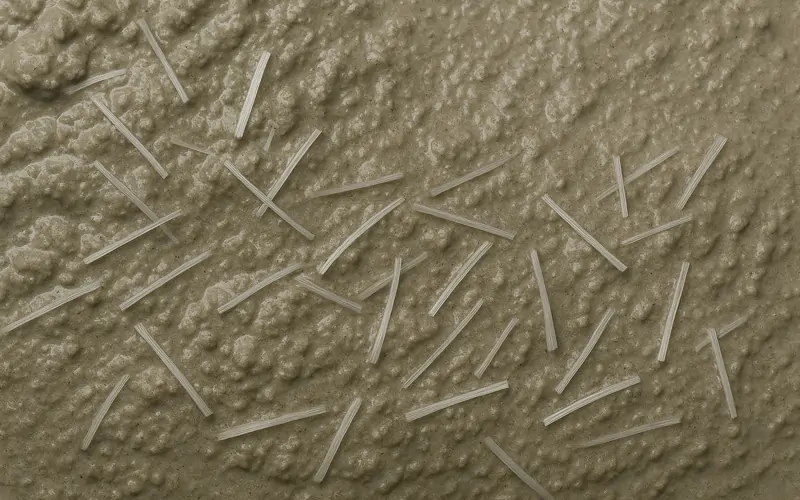

What is Fiber Mesh in Concrete?

Fiber mesh refers to a reinforcement method where small fibers (polypropylene, steel, glass, or natural fibers) are uniformly mixed into the concrete batch. Unlike wire mesh, which sits in a specific layer, fiber mesh disperses throughout the entire concrete matrix.

Types of Fiber Mesh

-

Polypropylene fibers (most common)

-

Steel fibers

-

Glass fibers

-

Cellulose (natural) fibers

How Fiber Mesh Works in Concrete

Fiber mesh acts as a micro-reinforcement, controlling plastic shrinkage cracks, improving impact resistance, and enhancing surface durability. It’s especially useful for thin slabs, overlays, and decorative concrete.

Common Applications of Fiber Mesh

-

Residential concrete slabs & sidewalks

-

Shotcrete applications (sprayed concrete)

-

Precast concrete products

-

Decorative concrete finishes

Pros of Fiber Mesh

-

Quick & easy to integrate during mixing

-

Uniform distribution of reinforcement

-

Reduces surface cracking & curling

-

No additional labor for placement

Cons of Fiber Mesh

-

Limited structural load-bearing capacity

-

Can be more expensive per cubic meter

-

May cause surface finish issues if overused

Wire Mesh vs Fiber Mesh: What Are the Key Differences?

| Feature | Wire Mesh | Fiber Mesh |

|---|---|---|

| Material Form | Steel grid sheets/rolls | Fibers mixed into concrete |

| Installation | Placed manually before pouring | Added during mixing process |

| Crack Control | Controls shrinkage & structural cracks | Controls surface & plastic shrinkage cracks |

| Structural Strength | High load-bearing capacity | Minimal structural enhancement |

| Rust Risk | Yes (if unprotected) | None (for synthetic fibers) |

| Labor Intensity | High | Low |

| Best for | Heavy-duty slabs, pavements | Residential slabs, overlays, quick repairs |

Cost Comparison: Wire Mesh vs Fiber Mesh

Material Costs Breakdown

-

Wire Mesh: Typically $0.50 to $1.00 per square foot.

-

Fiber Mesh: Around $6 to $10 per cubic yard of concrete.

Installation & Labor Costs

-

Wire Mesh requires placement, supports, and careful positioning, increasing labor costs.

-

Fiber Mesh eliminates separate installation steps, reducing labor expenses.

Long-term Cost Efficiency

While wire mesh is more labor-intensive, it can offer better structural performance for heavy loads. Fiber mesh, on the other hand, reduces cracking risks and repair costs for lighter applications.

Quick Cost Comparison Table

| Cost Factor | Wire Mesh | Fiber Mesh |

|---|---|---|

| Material Cost | Higher per area | Higher per volume |

| Labor Cost | High | Low |

| Maintenance | Moderate | Low |

| Lifecycle Value | Best for heavy-duty | Best for light-duty |

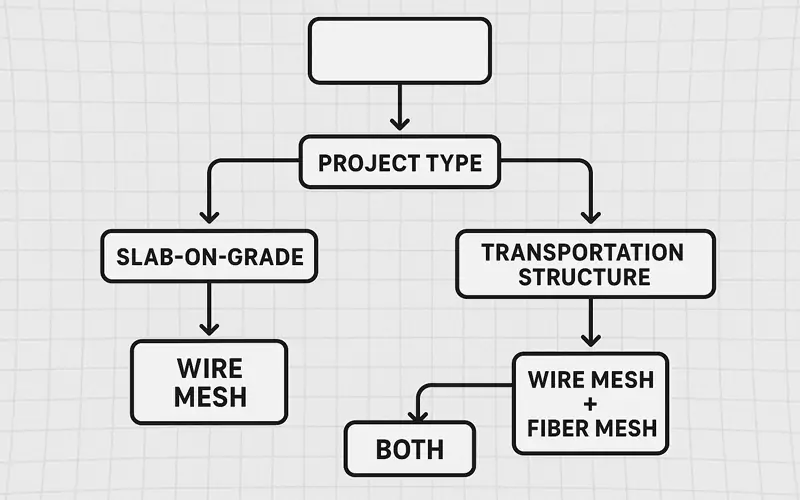

When to Use Wire Mesh and When to Use Fiber Mesh?

Best Use Cases for Wire Mesh

-

Industrial floors subject to heavy machinery

-

Roadways and commercial driveways

-

Projects with strict building code compliance

-

Large slabs requiring enhanced tensile strength

Best Use Cases for Fiber Mesh

-

Residential patios, sidewalks, and floors

-

Fast-track construction projects

-

Decorative concrete surfaces

-

Areas prone to shrinkage cracking

Can You Combine Both?

Yes! In high-performance applications, combining wire mesh for structural support with fiber mesh for shrinkage control offers a dual reinforcement system, maximizing concrete durability.

Case Studies & Real Examples

-

Warehouse slabs reinforced with wire mesh and fiber mesh to prevent both structural and surface cracks.

-

Residential basement floors using only fiber mesh for quick installation and surface crack resistance.

Expert Tips on Choosing Between Wire Mesh and Fiber Mesh

Evaluate Your Project Needs

-

Heavy load areas → Wire Mesh

-

Crack-prone surface → Fiber Mesh

-

Tight timelines & budgets → Fiber Mesh

Consider Local Building Codes

Always check regional regulations—some jurisdictions mandate wire mesh for specific structural applications.

Contractor Recommendations

Consult experienced contractors who can assess site conditions, usage patterns, and recommend the right reinforcement.

Avoid Common Selection Mistakes

-

Don’t assume fiber mesh replaces wire mesh in heavy-duty slabs.

-

Ensure proper dosage and mixing to avoid surface blemishes.

-

Don’t skip rust protection for wire mesh installations.

Conclusion: Which One Should You Choose?

If your project demands high load-bearing capacity, structural reinforcement, and code compliance, wire mesh remains the best choice.

For residential projects, shrinkage crack control, and quick installations, fiber mesh offers excellent benefits with less labor.

When in doubt, combining both methods can deliver superior results.

Frequently Asked Questions (FAQ)

Is Fiber Mesh Stronger Than Wire Mesh?

No, fiber mesh primarily controls surface cracking and does not replace the structural strength of wire mesh.

Can Fiber Mesh Completely Replace Wire Mesh?

For light-duty applications, yes. For heavy-duty structural slabs, no.

Which Is More Cost-Effective?

Fiber mesh reduces labor costs; wire mesh offers better long-term structural integrity.

Does Fiber Mesh Affect Concrete Finish?

If overused or improperly mixed, fibers may protrude on the surface, but proper finishing techniques can mitigate this.

How Long Do Wire Mesh and Fiber Mesh Last?

Wire mesh can corrode if unprotected, whereas synthetic fiber mesh is corrosion-resistant. Lifespan depends on environmental exposure and maintenance.