Whether you’re working in construction, pharmaceuticals, or food processing, understanding particle size is crucial. That’s where test sieves come in. In this comprehensive guide, we’ll explore what a test sieve is, how it works, the different types available, and how to choose the right one for your needs.

Table of Contents

ToggleWhat Is a Test Sieve?

A test sieve is a laboratory device used to separate particles by size. It typically consists of a wire mesh screen stretched over a circular metal frame. Materials are placed on the screen and shaken, allowing smaller particles to fall through while larger ones remain on top.

In simple terms, test sieves help determine the size distribution of granular or powdered substances — an essential part of quality control and material classification.

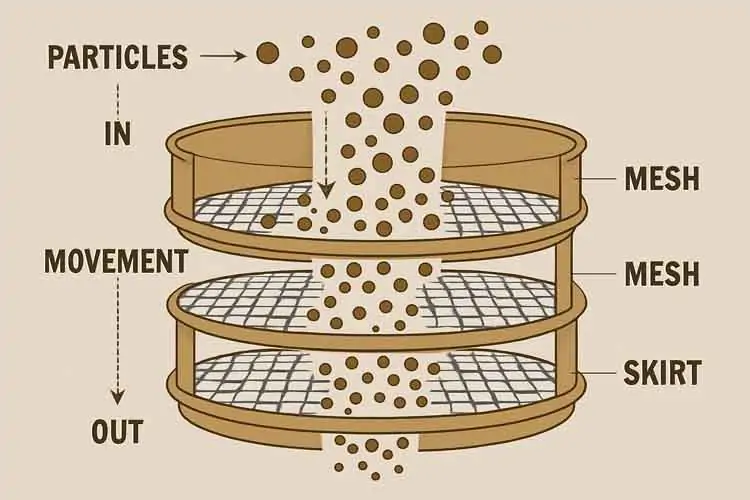

How Do Test Sieves Work? (With Diagrams)

Test sieves work through a process called sieving — the physical separation of particles based on their size using vibration or manual shaking. The test material is placed in a stack of sieves with progressively smaller mesh sizes from top to bottom.

The material is then agitated (mechanically or by hand), and particles pass through the screens according to their size.

Common Uses of Test Sieves Across Industries

Test sieves are used in a wide range of industries for quality assurance, material classification, and compliance testing:

-

Food & Beverage: Ensure consistency in flour, sugar, and spices.

-

Pharmaceuticals: Control powder particle sizes for tablets.

-

Construction & Aggregates: Classify sand, gravel, and cement.

-

Mining & Metallurgy: Size ore particles and minerals.

-

Chemicals & Plastics: Sort granules, resins, and polymers.

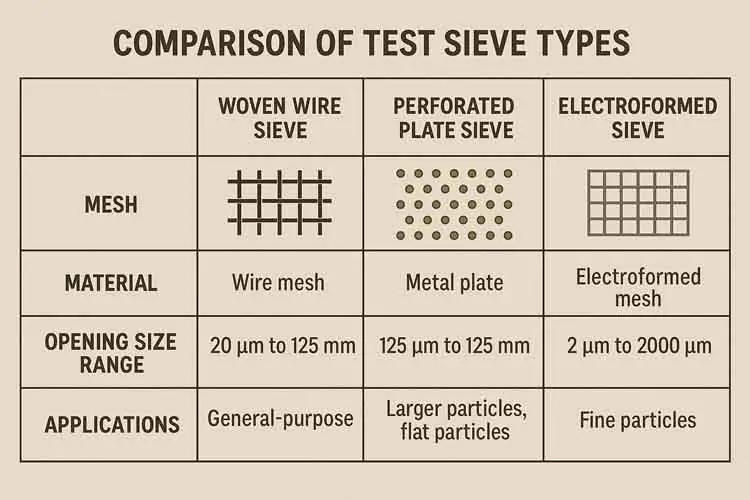

Types of Test Sieves: Which One Do You Need?

There are several types of test sieves, each designed for specific applications:

-

Woven Wire Mesh Sieves: Ideal for fine to medium particle analysis.

-

Perforated Plate Sieves: Used for coarser materials.

-

Wet-Wash Sieves: Designed for materials that clump or require liquid separation.

-

Air Jet Sieves: Ideal for ultra-fine powders using air suction.

You can also choose between full height and half height sieves depending on your sieve shaker or test method.

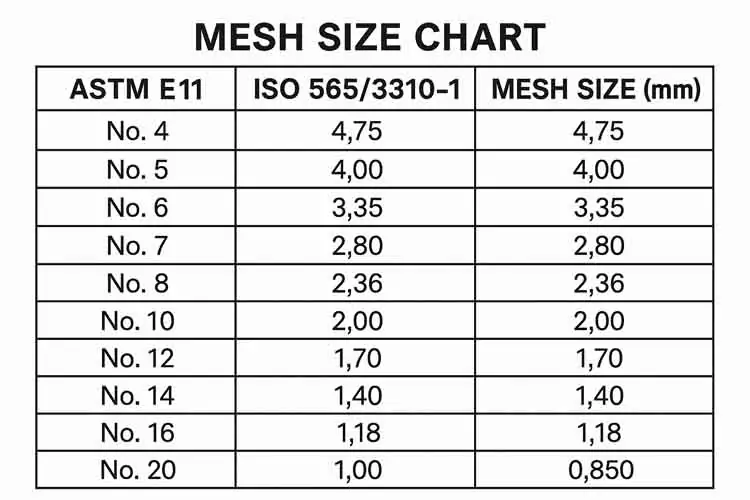

Mesh Size & Standards Explained

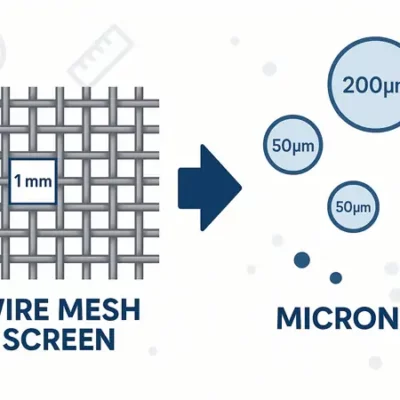

Mesh size refers to the number of openings per linear inch in a screen. The smaller the opening, the finer the mesh. Two widely used standards define mesh sizes:

-

ASTM E11 (U.S. Standard Sieve Series)

-

ISO 3310 (International Standard)

For example:

-

ASTM No. 10 → 2.00 mm opening

-

ASTM No. 100 → 150 µm opening

Understanding these specifications ensures you select the right sieve for your application.

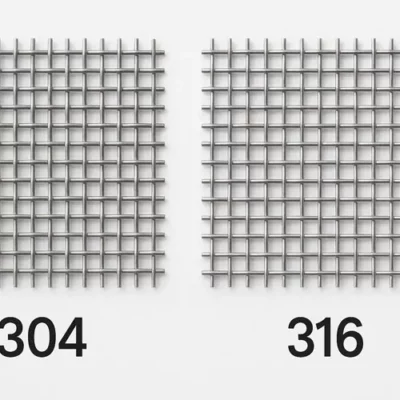

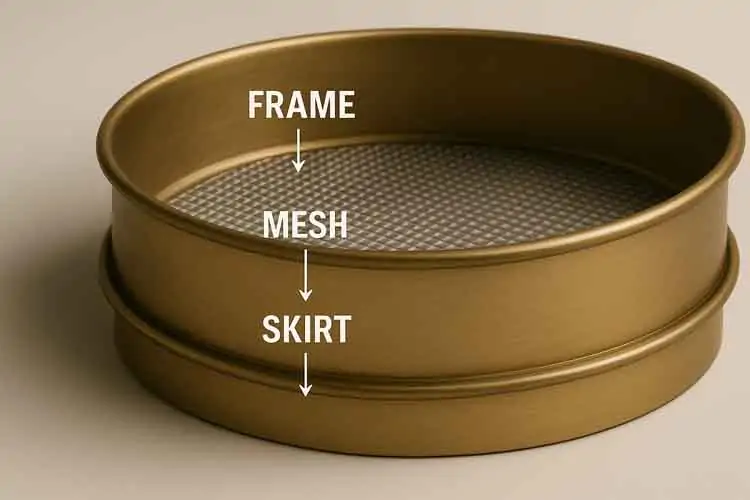

What Are Test Sieves Made Of? – Components Breakdown

A test sieve has three main components:

1. Wire Mesh Screen

Made from stainless steel or brass, this is the part that separates particles.

2. Frame

Holds the mesh in place. Common materials include:

-

Stainless steel (durable and corrosion-resistant)

-

Brass (conducts less heat, useful in labs)

3. Skirt

The extended bottom section allows stacking with other sieves and ensures a snug fit in sieve shakers.

Pros and Cons of Test Sieve Analysis

Advantages:

-

Cost-effective and easy to use

-

Provides reproducible results

-

Requires minimal equipment

-

Applicable in dry and wet analysis

Limitations:

-

Not suitable for ultra-fine materials (<20 µm)

-

Manual shaking can introduce human error

-

Limited throughput for large-volume samples

How to Choose the Right Test Sieve for Your Project

When selecting a test sieve, consider:

-

Material type (dry powder, aggregate, wet slurry)

-

Particle size range (microns to millimeters)

-

Industry standards (e.g. ASTM, ISO)

-

Frequency of use (occasional vs high-volume testing)

-

Budget (brass sieves are cheaper, but less durable)

Need expert advice? 👉 Contact Yeson Wire Mesh for a tailored recommendation

Sieve Accuracy: How to Ensure Reliable Results

Accuracy in sieving is essential. Here’s how to maintain it:

-

Certified Sieves: Verified to meet ASTM/ISO mesh tolerance

-

Calibration: Regular inspection with calibration spheres or inspection tools

-

Compliance Grades: Choose the right certification level:

-

Compliance (basic)

-

Inspection (medium precision)

-

Calibration (highest precision)

-

How to Analyze Certified Test Sieves

Sifting for the Facts

Examine how your sieve performs over time. Track performance to identify when recalibration or replacement is needed.

Quality and Characteristics

Look for smooth, burr-free mesh edges and well-marked frame labels with serial numbers and standard compliance.

Test Sieve Price Guide: What Should You Expect to Pay?

Prices vary by material, size, and certification level. Here’s a rough guide:

| Type | Price (USD) |

|---|---|

| Brass Sieve (8″ Diameter) | $45–$70 |

| Stainless Steel (Certified) | $80–$120 |

| Wet-Wash Sieves | $100–$150 |

| Perforated Plate Sieves | $65–$110 |

Buying tip: Always purchase from a reputable manufacturer like Yeson to ensure compliance and durability.

Sieve Cleaning and Maintenance Tips

Regular cleaning prevents contamination and extends lifespan:

-

Gently brush or air-blow particles

-

For fine mesh, use ultrasonic cleaners

-

Never scrub aggressively — it can damage the wire mesh

-

Store in dry, dust-free environments

Yeson Wire Cloth Test Sieves – Why Choose Us?

-

✅ Manufactured to ASTM E11 / ISO 3310

-

✅ Made with high-precision stainless steel

-

✅ Certified for inspection or calibration-grade testing

-

✅ Global shipping and expert technical support

Our sieves are trusted by labs and manufacturers worldwide. Browse our full product range or request a quote today!

Future Trends in Test Sieving

-

Smart Sieving: Integration with digital readouts and software

-

Automated Sieve Shakers: Reduce labor and improve consistency

-

Eco-Friendly Materials: Recyclable components and low-impact production

FAQs About Test Sieves

Q1: How long does a test sieve last?

A: With proper care, a quality sieve can last 2–5 years.

Q2: What is the difference between mesh and micron?

A: Mesh is the number of openings per inch; micron measures the actual size of the opening.

Q3: Can I use a test sieve for wet materials?

A: Yes — use a wet-wash sieve with a waterproof frame and mesh.

Q4: What’s the best sieve size for fine powders?

A: Typically, 200 mesh (75 µm) or finer, depending on your material.

Q5: How do I know if my sieve is certified?

A: Certified sieves come with documentation, serial number, and tolerance grade.