Table of Contents

ToggleOverview – Why Welded Wire Mesh is So Popular Today

Welded wire mesh is everywhere—from the fences around construction sites to the concrete reinforcement beneath your feet. This versatile material is a staple in industries like agriculture, infrastructure, architecture, and manufacturing due to its strength, durability, and adaptability.

But while it’s often praised for its practical uses, welded wire mesh isn’t a perfect solution for every situation. In this ultimate guide, we’ll explore both the benefits and drawbacks of using welded wire mesh, helping you make the right decision for your next project.

What is Welded Wire Mesh?

Welded wire mesh is made by welding horizontal and vertical wires at their intersections, creating a grid-like structure. This welding process gives the mesh its strength and rigidity, making it ideal for structural and containment applications.

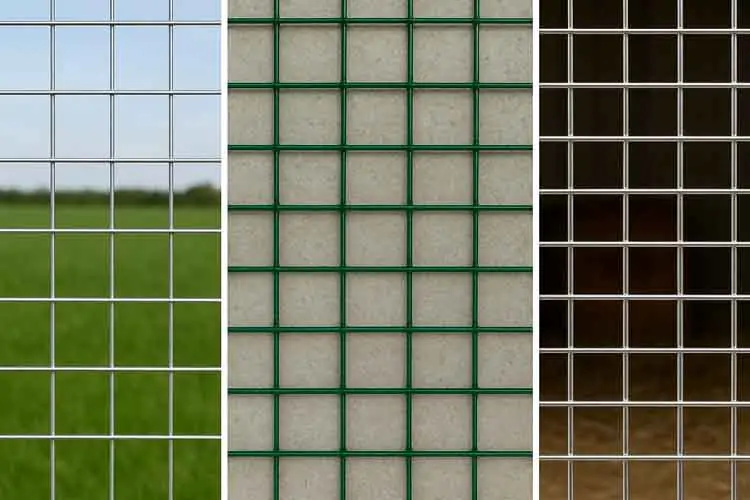

There are several common types of welded wire mesh, each suited for different environments and use cases.

Galvanized Welded Mesh

Coated with a protective layer of zinc, galvanized mesh resists corrosion and is suitable for outdoor use.

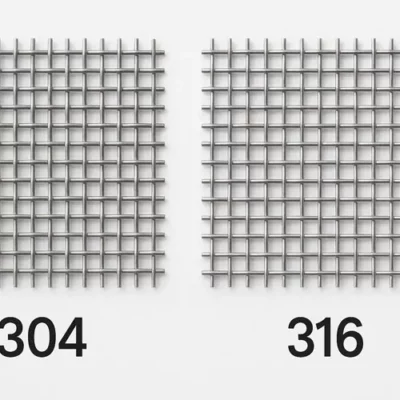

Stainless Steel Welded Mesh

Offers superior rust resistance and is used in environments requiring hygienic or corrosion-proof materials, such as food processing or marine applications.

PVC Coated Welded Mesh

Adds an extra layer of weather protection and color options. Often used in landscaping and decorative fencing.

12 Undeniable Benefits of Welded Wire Mesh

Here’s why professionals across multiple sectors rely on welded wire mesh:

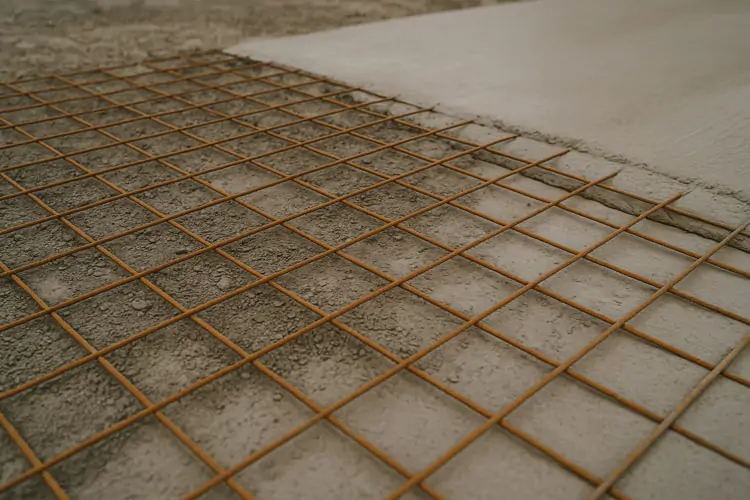

1. Structural Strength and Load Capacity

Thanks to welded intersections, this mesh provides superior structural integrity—ideal for retaining walls, concrete slabs, and reinforcement grids.

2. Corrosion and Weather Resistance

Materials like galvanized or stainless steel extend lifespan even in rain, humidity, or coastal environments.

3. Versatility Across Industries

Used in construction, agriculture, security, landscaping, and industrial partitions. One product, countless solutions.

4. Long-Term Durability

Welded mesh doesn’t fray or unravel like woven options. With proper coating, it can last for decades.

5. Cost Efficiency for Large Projects

Especially when purchased in rolls or large panels, it’s an affordable solution per square foot.

6. Minimal Maintenance Needs

After installation, it requires little to no upkeep. No painting, no tightening, no sagging.

7. Customization Options

Available in various wire gauges, mesh openings, panel sizes, and coatings—ideal for tailored projects.

8. Easy to Cut and Shape

Can be trimmed to fit exact dimensions using simple tools.

9. Pest and Rodent Resistance

Acts as a barrier to rodents, snakes, and small animals when installed around gardens or vents.

10. Eco-Friendly

Steel is recyclable and often made from recycled content, making it a greener option.

11. Building Code Compliance

Commonly meets standards for reinforcement and safety in many regions.

12. Security and Containment

Provides a physical barrier that’s difficult to climb or tamper with—used in high-security zones.

10 Real Drawbacks You Need to Know

While effective, welded wire mesh has limitations that could make it unsuitable in some situations.

1. Rigid – Not Suitable for Uneven Ground

The lack of flexibility makes it difficult to install on sloped or curved terrain without special preparation.

2. Higher Upfront Cost Compared to Chain-Link

Though cost-effective in bulk, initial investment is higher than other basic fencing options.

3. Limited Privacy

Its open-grid design makes it unsuitable when privacy is a concern, such as in residential backyards.

4. Vulnerable to Rust if Poorly Treated

If welds aren’t properly coated or if the galvanization wears off, corrosion can develop over time.

5. Not Soundproof or Weatherproof

Unlike solid barriers, welded mesh allows noise, wind, and rain to pass through freely.

6. Heavy and Bulky

Large panels or rolls can be difficult to transport and maneuver without equipment.

7. Requires Skilled Installation

Improper cutting or bending can damage the structure and reduce its integrity.

8. Weld Points Can Break Under Repeated Stress

In environments with vibration or movement, weld fatigue may occur over time.

9. Aesthetic Limitations

The industrial look may not match the visual appeal of wood, vinyl, or ornamental fencing.

10. Not Suitable for Temporary Installations

Its rigid nature and installation demands make it less ideal for short-term or mobile setups.

When is Welded Wire Mesh the Right Choice?

Welded mesh is ideal if you need:

-

High strength for structural reinforcement

-

Durability in outdoor or corrosive environments

-

Security for fencing, containment, or industrial safety

-

Low maintenance for long-term use

-

Rodent or pest control in agricultural or home settings

When You Should Avoid Welded Wire Mesh

You may want to consider other options if:

-

You need a flexible mesh for curved or uneven areas

-

Privacy, sound reduction, or aesthetics are top priorities

-

Budget is limited and you prefer cheaper solutions like chain-link or woven mesh

-

You’re planning a temporary setup or rental installation

Comparison Table – Welded Mesh vs Chain-Link vs Woven Wire

| Feature | Welded Wire Mesh | Chain-Link | Woven Wire |

|---|---|---|---|

| Strength | ★★★★★ | ★★★ | ★★ |

| Flexibility | ★ | ★★★★ | ★★★★★ |

| Cost | ★★★★ | ★★★★★ | ★★★ |

| Security | ★★★★★ | ★★★★ | ★★ |

| Privacy | ★ | ★★ | ★ |

| Aesthetic Appeal | ★★ | ★★★ | ★★ |

| Ease of Installation | ★★★ | ★★★★★ | ★★★ |

How to Choose the Right Welded Wire Mesh for Your Project

When selecting a welded mesh, consider:

-

Material: Galvanized (budget), stainless (anti-corrosion), PVC-coated (color & outdoor use)

-

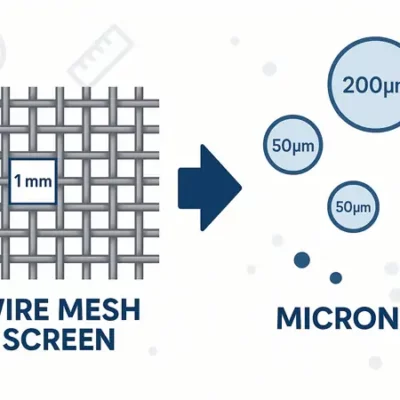

Wire gauge: Thicker for strength, thinner for flexibility

-

Aperture size: Smaller for pest control, larger for visibility

-

Environment: Humid or chemical-rich environments need rust-proof materials

FAQs About Welded Wire Mesh

Q: Is welded wire mesh better than chain-link fencing?

A: Yes, for strength and security. But chain-link is more flexible and cheaper.

Q: How long does welded mesh last?

A: With proper coating, it can last 10–30 years depending on material and environment.

Q: Can I install it myself?

A: For small panels, yes. But large installations may need professional tools or labor.

Q: Does it rust?

A: Galvanized and stainless versions resist rust. Untreated or scratched mesh can corrode.

Final Verdict – Is Welded Wire Mesh Worth It?

If your project demands strength, durability, and versatility, welded wire mesh is a top-tier choice. While it’s not suited for every application—particularly where privacy or flexibility is needed—it remains one of the most reliable, long-lasting, and cost-effective materials in fencing and construction.

Want expert advice on selecting the right welded mesh for your project?

👉 Explore our welded wire mesh products now