Table of Contents

ToggleIntroduction

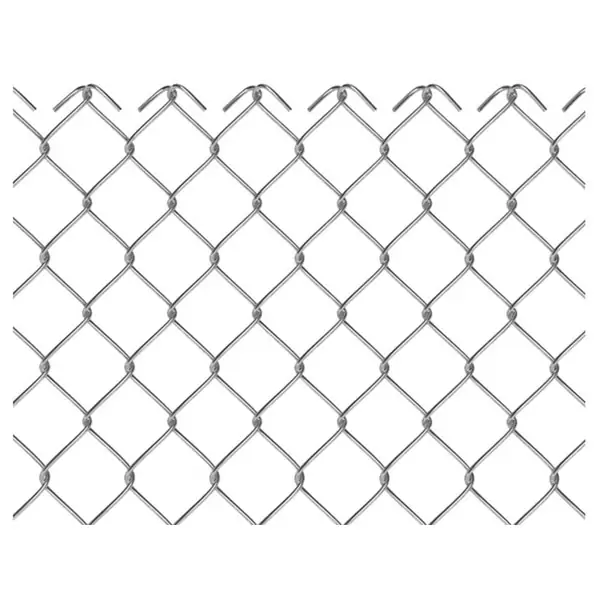

Welded wire mesh is a widely used metal fabric known for its strength, stability, and versatility. It is manufactured by welding intersecting steel wires at their crossing points, forming a rigid and uniform grid structure. Compared with woven wire mesh, welded wire mesh offers better load-bearing capacity, dimensional accuracy, and long-term durability.

Due to these advantages, welded wire mesh is extensively applied in construction, agriculture, security fencing, industrial protection, and architectural design. This article provides a comprehensive overview of its types, benefits, materials, manufacturing methods, and applications.

Chapter 1: What is Welded Wire Mesh?

Welded wire mesh is a prefabricated metal grid made by electrically welding longitudinal and transverse wires together at regular intervals. Each intersection is permanently bonded, creating a strong and stable structure.

The mesh is typically produced in rolls or rigid panels and can be customized in terms of wire diameter, mesh opening, sheet size, and surface treatment. Common materials include carbon steel, stainless steel, and aluminum.

Unlike woven mesh, welded wire mesh does not shift or unravel, making it suitable for structural and safety-critical applications.

Chapter 2: What Are the Different Types of Welded Wire Mesh?

Square Welded Wire Mesh

Square welded wire mesh features equal spacing in both directions, forming square openings. It provides balanced strength and is commonly used in fencing, concrete reinforcement, and safety barriers.

Rectangular Welded Wire Mesh

Rectangular welded mesh has elongated openings that provide higher strength in one direction. It is often used in shelves, partitions, and construction reinforcement systems.

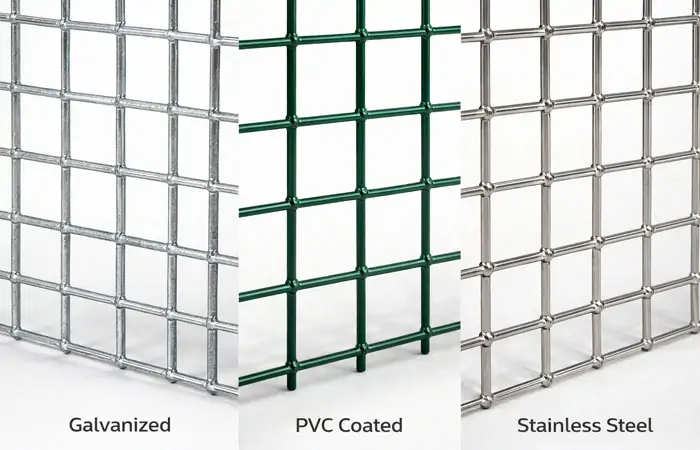

PVC Welded Wire Mesh

PVC welded wire mesh is coated with a plastic layer over galvanized wire. This coating improves corrosion resistance, weather durability, and visual appearance. It is widely used in gardens, residential fencing, and animal enclosures.

Galvanized Welded Wire Mesh

Galvanized welded wire mesh is coated with zinc to prevent rust and oxidation. It is suitable for outdoor and humid environments and is available in hot-dip and electro-galvanized forms.

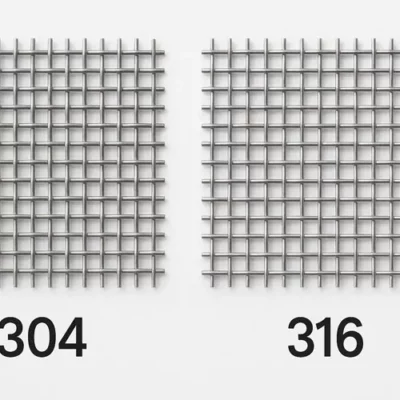

Welded Stainless Steel Wire Mesh

Stainless steel welded mesh is manufactured from grades such as 304 and 316 stainless steel. It offers excellent resistance to corrosion, chemicals, and high temperatures, making it ideal for food, pharmaceutical, and marine applications.

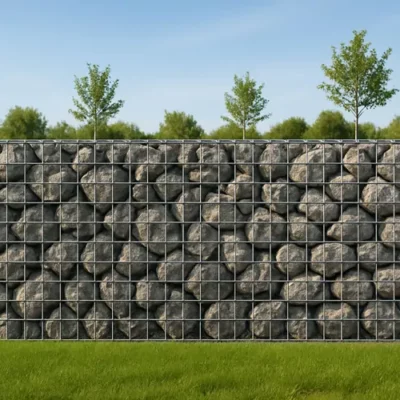

Welded Wire Fencing

Welded wire fencing is designed for perimeter protection and boundary control. It combines welded mesh panels with steel posts to create durable fencing systems for residential, commercial, and industrial sites.

Heavy Welded Wire Mesh

Heavy welded wire mesh uses thick wire diameters and reinforced welding techniques. It is suitable for high-load and high-security applications such as mining protection and industrial safety barriers.

Chapter 3: What are the Benefits and Applications of Using Welded Wire Mesh?

Benefits of Using Welded Wire Mesh

Welded wire mesh offers multiple advantages, including:

-

High structural strength

-

Excellent dimensional stability

-

Long service life

-

Easy installation

-

Low maintenance requirements

-

Cost-effective performance

Its welded intersections ensure consistent load distribution and resistance to deformation.

Applications of Welded Wire Mesh

Welded wire mesh is widely used in:

-

Concrete reinforcement

-

Perimeter fencing

-

Animal cages and pens

-

Machine guarding

-

Storage systems

-

Architectural façades

Frequently Asked Questions

What is welded wire mesh and how is it produced?

Welded wire mesh is produced by arranging steel wires in a grid pattern and welding each intersection using resistance welding technology. This creates a rigid and durable structure.

Which types of welded wire mesh are available?

Common types include square mesh, rectangular mesh, galvanized mesh, PVC-coated mesh, stainless steel mesh, fencing mesh, and heavy-duty mesh.

What are the main benefits of using welded wire mesh?

Key benefits include high strength, corrosion resistance, dimensional accuracy, easy installation, and long-term durability.

How should I select the right welded wire mesh for my project?

Selection depends on application environment, load requirements, corrosion resistance, material type, and applicable standards. Consulting a professional supplier is recommended.

What are the typical applications of welded wire mesh?

Typical applications include construction reinforcement, security fencing, livestock enclosures, industrial protection, and architectural decoration.

How does welded wire mesh enhance security and durability in fencing projects?

Its welded joints prevent wire movement and cutting, while galvanized or coated surfaces protect against corrosion, ensuring long-term performance.

Chapter 4: What are the methods used for manufacturing galvanized wire mesh?

Hot Dip Galvanization

Hot-dip galvanization involves immersing the welded mesh in molten zinc. This process forms a thick protective layer that provides superior corrosion resistance for outdoor and marine environments.

Electro Galvanizing

Electro-galvanizing applies a thin zinc coating through an electrochemical process. It offers a smooth surface finish and is suitable for indoor or light-duty applications.

Chapter 5: What materials are used for welded wire mesh?

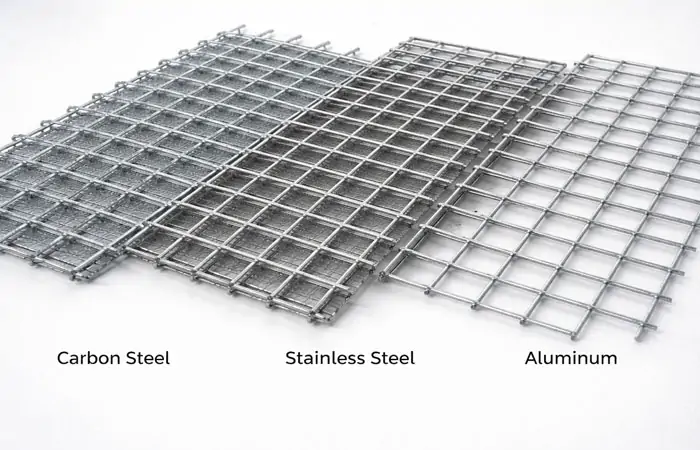

Carbon Steel

Carbon steel is the most common material due to its high strength and cost efficiency. It is usually galvanized to improve corrosion resistance.

Stainless Steel

Stainless steel offers excellent resistance to rust, chemicals, and heat, making it ideal for demanding environments.

Aluminum

Aluminum welded mesh is lightweight and corrosion-resistant, suitable for decorative and lightweight structural applications.

Brass

Brass mesh provides good corrosion resistance and attractive appearance. It is mainly used in decorative and specialty applications.

Copper

Copper welded mesh offers excellent electrical conductivity and corrosion resistance and is used in electromagnetic shielding and industrial filtration.

Chapter 6: What are welded wire mesh panels?

Welded wire mesh panels are rigid, pre-cut sheets manufactured for fast installation and consistent performance. They are commonly used in fencing, storage cages, and machine guards.

Characteristics of Galvanized Steel Mesh Panels

-

High mechanical strength

-

Uniform mesh openings

-

Excellent corrosion resistance

-

Long service life

Applications of Galvanized Mesh Panels

-

Perimeter fencing

-

Warehouse partitions

-

Equipment enclosures

-

Construction barriers

Packaging of Welded Wire Mesh Panels

Mesh panels are usually packed with steel straps and protective films. Pallets or wooden crates are used for long-distance transportation.

Price of Galvanized Mesh Panel

The price depends on wire diameter, mesh size, zinc coating thickness, panel dimensions, and order quantity. Bulk orders generally offer better pricing.

Chapter 7: What are the general specifications for welded wire mesh?

Material

Common materials include carbon steel, stainless steel, aluminum, brass, and copper.

Shape and Size

Mesh openings can be square or rectangular. Panel and roll sizes are customizable according to project requirements.

Cutting and Forming

Welded mesh can be cut, bent, and shaped without losing structural integrity, enabling flexible installation.

Lapping and Clearance

Proper overlap and clearance ensure effective reinforcement and load transfer in construction applications.

Vibrating

Vibrating during concrete placement improves bonding between welded mesh and concrete, enhancing structural performance.

Chapter 8: What are the benefits and uses of welded wire fabric in concrete?

Benefits of Welded Wire Fabric in Concrete

Higher Design Strength

Welded wire fabric provides uniform reinforcement, improving load distribution and structural strength.

Better Bonding

The welded structure ensures strong bonding between steel and concrete.

Effective Crack Resistance

It controls shrinkage and temperature cracks, enhancing durability.

Economical

Prefabricated mesh reduces labor costs and material waste.

Flexible in Handling and Placing

Lightweight panels are easy to transport and install on-site.

Uses of Welded Wire Fabric in Concrete

-

Floor slabs

-

Pavements

-

Bridge decks

-

Retaining walls

-

Precast components

Applications of Welded Wire Mesh

In concrete construction, welded wire mesh is used for reinforcement, crack control, and load distribution.

Chapter 9: What are the key terms associated with welded wire mesh?

Common technical terms include:

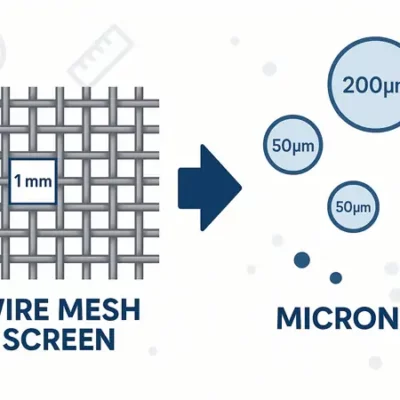

-

Wire Diameter: Thickness of the wire

-

Mesh Opening: Distance between wires

-

Zinc Coating Weight: Thickness of galvanization

-

Tensile Strength: Resistance to breaking

-

Yield Strength: Deformation threshold

-

Panel Size: Overall dimensions

-

Weld Strength: Bonding quality at intersections

Understanding these terms helps buyers select suitable products and ensure quality compliance.