Table of Contents

ToggleIntroduction

Metal grating is a critical component in industrial flooring, construction platforms, drainage systems, and structural walkways. Known for its high load-bearing capacity, durability, and ventilation performance, metal grating is widely used in construction, infrastructure, manufacturing plants, energy facilities, and municipal engineering.

This complete guide explains:

-

What metal grating is

-

Types of steel grating and bar grating

-

Materials and surface treatments

-

International standards and sizes

-

Heavy duty vs light duty classifications

-

Industrial applications and installation

-

How to choose the right metal grating

If you are sourcing metal grating for a project, this article will help you make an informed decision.

What Is Metal Grating?

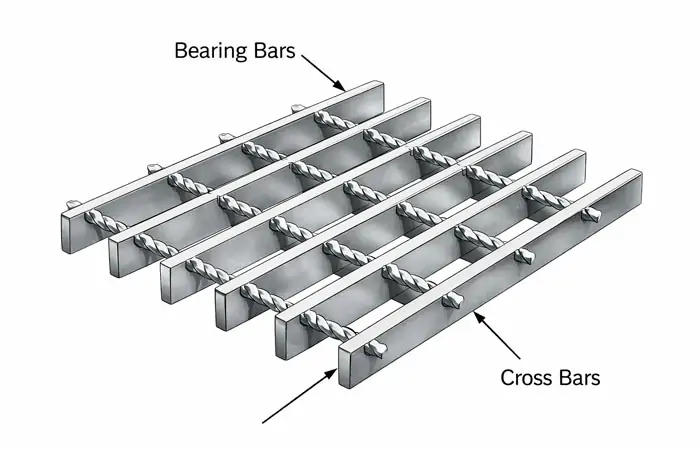

Metal grating is an open-grid assembly of metal bars, typically made from steel, stainless steel, or aluminum. It is manufactured by welding, pressing, or swaging bearing bars and cross bars to form a rigid load-bearing panel.

In construction, metal grating is used to provide:

-

Structural support

-

Drainage and airflow

-

Slip resistance

-

Safe walking surfaces

-

Light transmission

The term “grating” generally refers to industrial flooring panels, while “grate” often refers to drainage covers or trench grates. In structural engineering, steel grating plays a key role in platforms, catwalk grating, and heavy-duty flooring systems.

Main Types of Metal Grating

There are several types of metal grating depending on manufacturing method and application.

1. Welded Steel Grating

Welded steel grating is the most commonly used industrial grating. It is manufactured by automatically resistance-welding cross bars to bearing bars.

Features:

-

High strength-to-weight ratio

-

Strong load-bearing performance

-

Suitable for heavy duty steel grating applications

-

Cost-effective for large projects

Common uses:

-

Industrial steel grating platforms

-

Metal grating walkway systems

-

Steel grating floor in factories

-

Heavy duty welded grating for logistics centers

Galvanized welded steel grating is widely used outdoors due to corrosion resistance.

2. Press-Locked and Swaged Grating

Press-locked grating is produced by mechanically locking cross bars into bearing bars. Swaged grating uses hydraulic pressure for bar insertion.

Advantages:

-

Clean appearance

-

Architectural applications

-

Suitable for custom metal grating projects

-

Ideal for decorative metal grates

Often used in:

-

Commercial building flooring

-

Ventilation panels

-

Metal grate frame systems

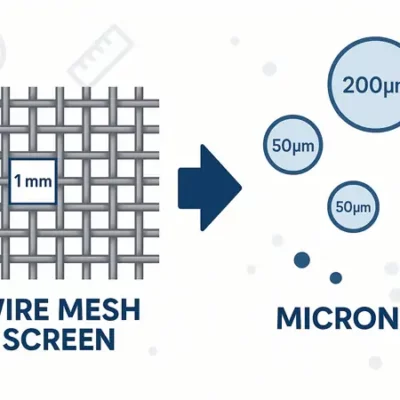

3. Expanded Metal Grating

Expanded metal grating is made by slitting and stretching metal sheets to form a diamond mesh pattern.

Characteristics:

-

Lightweight

-

Anti-slip surface

-

Cost-efficient

-

Used as expanded metal floor grating

Applications include:

-

Industrial walkways

-

Stair treads

-

Machinery platforms

4. Bar Grating Variations

Bar grating can be manufactured from:

-

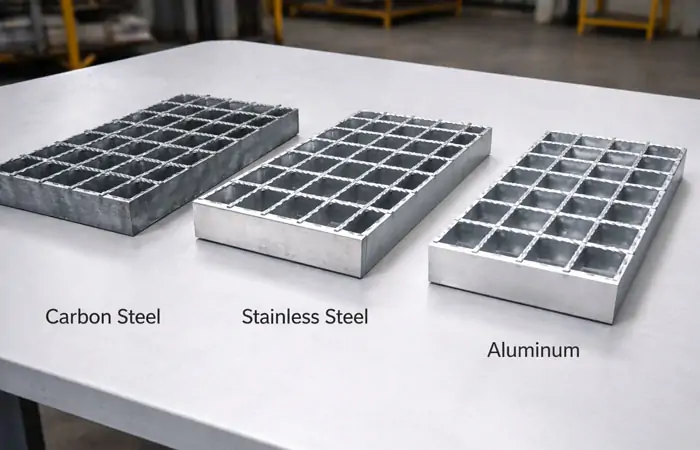

Carbon steel grating

-

Galvanized steel grating

-

Stainless steel grating

-

Aluminum grating

Each material provides specific mechanical and corrosion-resistant properties depending on the working environment.

Materials Used in Metal Grating

Choosing the correct metal grating material depends on load requirements and environmental exposure.

Carbon Steel Grating

Carbon steel is widely used due to its strength and affordability.

-

Suitable for heavy duty floor grating

-

Ideal for industrial metal grating

-

Often hot-dip galvanized for corrosion protection

Galvanized Steel Grating

Hot dip galvanized steel grating is coated with zinc to resist rust.

Benefits:

-

Excellent corrosion resistance

-

Long service life

-

Low maintenance

-

Ideal for outdoor steel grating walkway systems

Common in:

-

Bridge grating

-

Highway platforms

-

Driveway drain grates

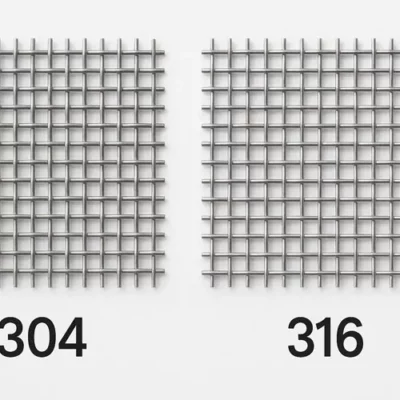

Stainless Steel Grating

Stainless steel grating provides superior corrosion resistance.

Applications:

-

Food processing plants

-

Chemical facilities

-

Marine environments

-

Stainless steel drain grate systems

Heavy duty stainless steel grating is preferred in highly corrosive areas.

Aluminum Grating

Aluminum grating is lightweight and corrosion-resistant.

Advantages:

-

Easy installation

-

Suitable for rooftop walkways

-

Marine and offshore structures

-

Architectural applications

Metal Grating Standards and Specifications

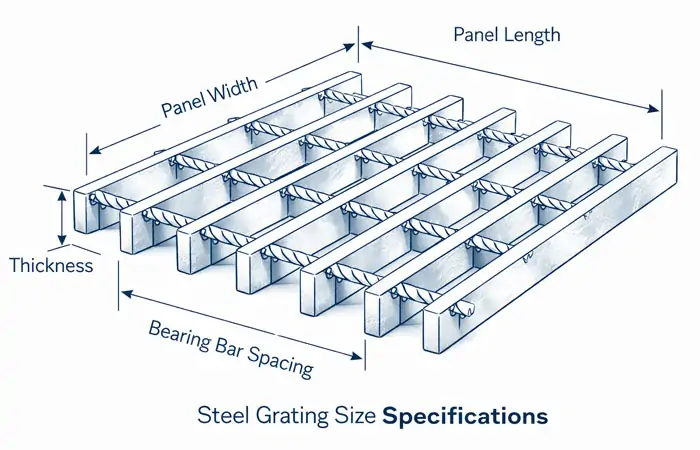

Metal grating sizes and specifications vary depending on standards and load requirements.

Key Technical Parameters:

-

Bearing bar thickness

-

Bearing bar spacing (commonly 30mm, 40mm)

-

Cross bar spacing

-

Surface type: plain or serrated

-

Load classification

Surface Options

-

Plain surface

-

Serrated steel grating (anti-slip)

Standard Sizes

Typical steel grating sizes include:

-

3ft × 20ft panels

-

Custom cut-to-size metal grating sheets

-

Heavy duty grates with reinforced bearing bars

For structural steel grating, international standards such as ANSI/NAAMM, BS, and DIN may apply depending on the project region.

Common Applications of Metal Grating

Metal grating is used across multiple industries.

Flooring and Walkways

-

Metal grating floor systems

-

Steel grating floor panels

-

Heavy duty grating for factories

-

Metal grating walkway in plants

-

Catwalk grating systems

Its open-grid structure allows water, oil, and debris to pass through, improving safety.

Stair Treads and Platforms

Steel grating stairs are widely used in:

-

Industrial towers

-

Warehouses

-

Energy facilities

Grating stair treads provide:

-

Slip resistance

-

Structural strength

-

Easy drainage

Drainage and Trench Systems

Drain grates and trench grates are essential in urban and industrial drainage.

Common products include:

-

Steel drain grate

-

Metal grate for drain

-

Driveway drain grates

-

Road grating

-

Decorative metal grates for windows

Galvanized steel drain grate systems are highly durable for municipal infrastructure.

Construction and Infrastructure

Metal grating in construction supports:

-

Structural steel platforms

-

Bridge grating

-

Sidewalk grating

-

Highway maintenance platforms

Heavy duty metal grates are required for high-load industrial environments.

Heavy Duty vs Light Duty Metal Grating

Load classification determines whether heavy duty steel grating is required.

Light Duty Grating

-

Pedestrian walkways

-

Rooftop access

-

Decorative applications

Heavy Duty Steel Grating

-

Truck loading zones

-

Industrial flooring

-

Warehouse logistics platforms

-

Offshore structures

Heavy duty grates have thicker bearing bars and higher load-bearing capacity.

Custom Metal Grating Solutions

For B2B buyers, custom grating fabrication is often required.

Customization options include:

-

Special metal grating sizes

-

Custom grating frames

-

Galvanized, painted, or powder-coated finish

-

Stainless steel grade selection

-

Serrated surface for anti-slip

Professional metal fabricators can produce steel bar grating near specific project requirements.

Installation of Metal Grating

Proper installation ensures structural performance.

Installation Methods:

-

Welding

-

Bolted clamps

-

Grating clips

-

Frame support systems

A metal grate frame is often installed to secure panels in drainage systems or platforms.

Routine inspection is recommended to ensure long-term durability.

How to Choose the Right Metal Grating

When selecting metal grating, consider:

-

Load requirements

-

Corrosion environment

-

Surface anti-slip needs

-

Drainage capacity

-

Budget constraints

Material Comparison

| Material | Strength | Corrosion Resistance | Cost | Application |

|---|---|---|---|---|

| Carbon Steel | High | Moderate | Low | Industrial flooring |

| Galvanized Steel | High | High | Medium | Outdoor platforms |

| Stainless Steel | High | Excellent | High | Chemical & food plants |

| Aluminum | Medium | High | Medium | Lightweight walkways |

Metal Grating Sizes and Purchasing Guide

Steel grating sizes vary depending on load and application.

Typical parameters:

-

Bearing bar height: 25mm–100mm

-

Thickness: 3mm–10mm

-

Panel width: customized

-

Length: cut-to-order

Pricing Factors:

-

Material type

-

Galvanizing process

-

Load rating

-

Quantity ordered

-

Custom fabrication

Bulk B2B orders often receive competitive pricing and export-ready packaging.

Frequently Asked Questions

What is steel grating used for?

Steel grating is used for industrial flooring, drainage covers, stair treads, catwalks, bridge decks, and heavy duty platforms due to its strength and durability.

What is the difference between bar grating and expanded metal?

Bar grating uses welded bearing bars and cross bars for high load capacity, while expanded metal is stretched from metal sheets and is lighter but less load-bearing.

Is galvanized steel grating rust-proof?

Hot dip galvanized steel grating offers excellent corrosion resistance and is suitable for outdoor use, but long-term exposure in extreme environments may still require maintenance.

What size metal grating do I need?

Size depends on load requirements, span length, and application type. Heavy duty grating requires thicker bearing bars and smaller spacing.

Conclusion

Metal grating is an essential industrial product used in construction, drainage, infrastructure, and heavy-duty flooring systems. From welded steel grating to stainless steel drain grates, selecting the right type and material ensures structural safety, durability, and cost efficiency.

Whether you require galvanized steel grating for outdoor walkways or heavy duty steel bar grating for industrial platforms, working with an experienced manufacturer ensures compliance with standards and long-term performance.

For bulk orders, custom metal grating sizes, or export inquiries, contact our team for technical support and competitive quotations.