When it comes to PVC coated welded mesh projects, ensuring high-quality results is critical. Whether you’re planning to build a fence, reinforce a structure, or create a DIY project, the durability and strength of welded mesh play a vital role. By following the right techniques and paying attention to details, you can significantly improve the quality of your PVC coated welded mesh projects. In this comprehensive guide, we’ll walk you through the process and provide valuable tips to achieve great results.

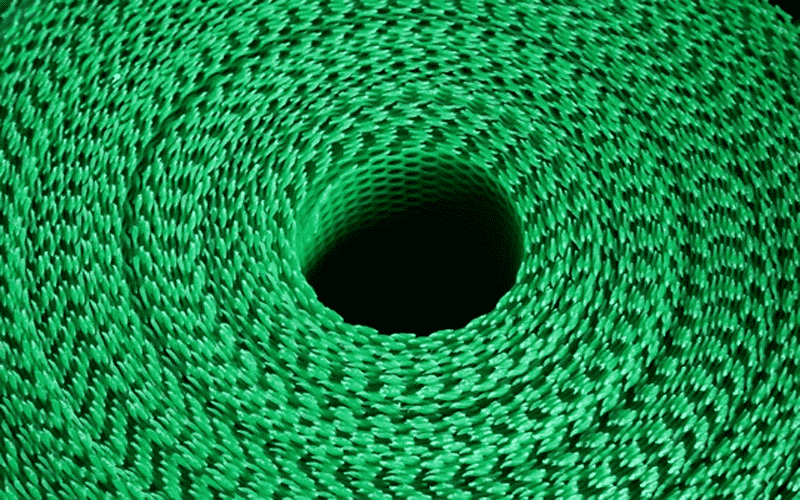

1. Select high-quality PVC coated welded wire mesh:

The first step in improving the quality of any PVC coated welded mesh project is choosing a quality material. Choose PVC coated welded mesh that is durable, corrosion resistant and suitable for your specific requirements. Consider the size of the rectangular or square opening and the gauge of the wires. Investing in a quality grid can help you avoid potential problems in the long run.

2. Proper measurement and planning:

Meticulous measurements and careful planning are essential before starting any project. Accurate measurements will ensure you are purchasing the correct amount of welded PVC mesh, saving you time and money. Plan the size and layout of the project, taking into account any obstructions or irregularities. Make sure to mark the location of the pole or frame supports so you can install them later.

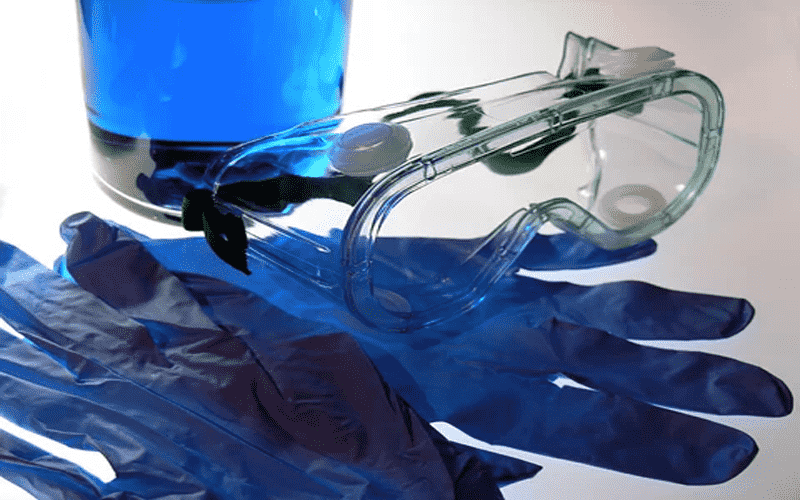

3. Safety precautions:

Safety precautions must be taken when working with PVC coated welded mesh. Always wear protective equipment such as gloves, gas masks and safety glasses to avoid injury from sharp edges or flying debris. Also, make sure the work area is well ventilated to prevent inhalation of harmful fumes while cutting or welding.

4. Cutting of PVC welded mesh:

Once you’ve measured and planned your project, it’s time to cut your PVC welded mesh to the desired dimensions. Use a heavy duty wire cutter or with an angle grinder to cut. Remember to leave a portion of overlap space or the required margin. Make sure the edges are smooth and free of rough spots to avoid injuries during installation.

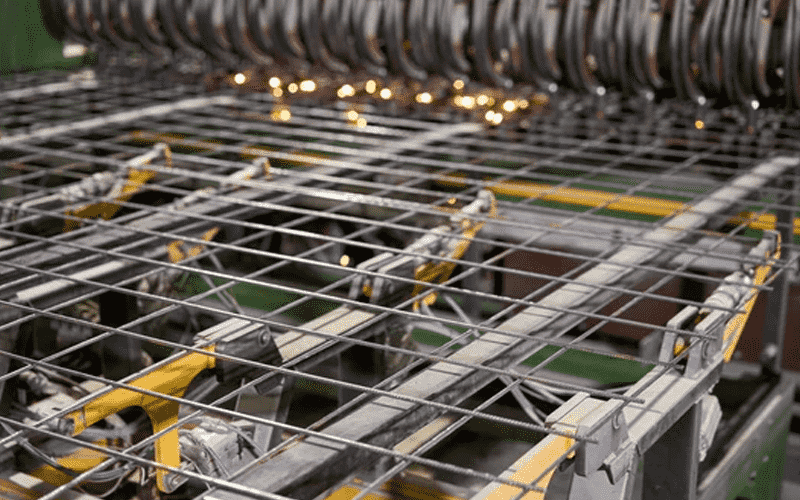

5. Welding of PVC welded mesh:

Proper welding is critical to the strength and durability of your PVC welded mesh project. If you are using PVC coated mesh, avoid exposing the welded area to excessive heat as this may damage the protective coating. Use high-quality welding equipment and follow the manufacturer’s guidelines for best results. Practice on a small piece of scrap grid before working on your actual project to make sure you have the right setup and technique.

6. Fasten the PVC welded mesh to the structure:

Properly securing welded PVC mesh is critical to maintaining the integrity of your project. Whether you are attaching the mesh to a rod, frame or any other structure, use suitable fasteners such as screws, nuts or bolts. Make sure the mesh is taut and stretched evenly to prevent sagging or loosening. For larger projects, consider using a tensioner for added stability.

7. Regular cleaning and maintenance:

Regular maintenance is necessary to ensure the long-term quality of your PVC welded mesh project. Periodically wash welded mesh with mild soap and water to remove dirt, debris or corrosive substances. Inspect welded seams for signs of wear or damage and repair or replace any damaged areas immediately.

8. Add aesthetics and finishing touches:

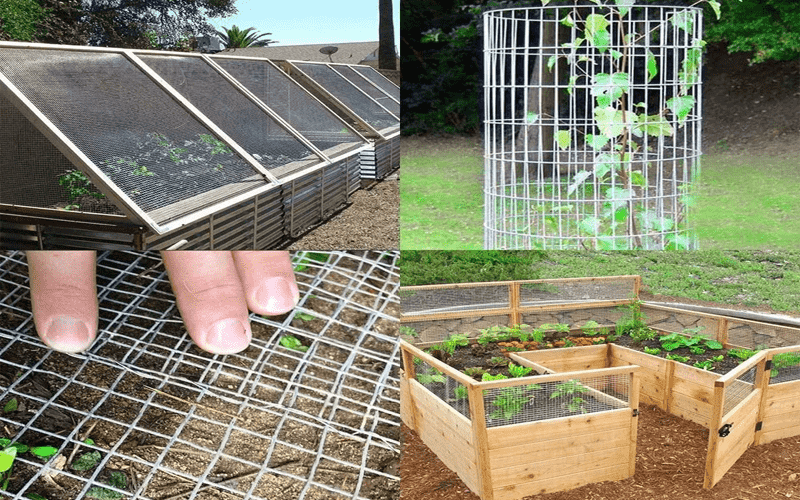

While the primary purpose of a PVC coated welded mesh project may be functional, adding an aesthetic element can enhance its overall appeal. Consider painting the grid with an appropriate exterior paint or coating to match your desired color scheme. Additionally, incorporating decorative elements such as plants, lattice panels or climbing vines can further enhance the visual appeal and seamlessly blend the project with its surroundings.

In conclusion for the quality of your project, it is important to pay attention to details and follow practices. You can achieve excellent results by choosing quality materials, taking accurate measurements, implementing safety procedures, and paying attention to maintenance. Remember, a well-crafted PVC coated welded wire mesh project not only serves its intended purpose, but also adds value and a sense of craftsmanship to your surroundings. So grab your tools, unleash your creativity, and start creating quality PVC coated welded mesh projects that will stand the test of time.

Hello,we are YESON,Professional Wire Mesh Fence Manufacturer.

We have been doing wire mesh fence for more than 30 years,We have been absorbed in high quality wire mesh production from the beginning.

The main products we offer include 358 Anti Climb Fence, Temporary fence, Chain link fence, BRC fence, Wrought iron fence, Crowd control barrier, Razor wire and Fence accessories. We also offer Gabion mesh, Defensive barrier, Hexagonal mesh, Welded mesh, Window screens and Crimped wire mesh, Plastic netting, Geogrid, Wire mesh container. We have established business relationships with customers in the domestic market and export to Hong Kong, Europe, the United States, Southeast Asia, the Middle East and Africa with our high quality products, timely delivery, reasonable prices and excellent service.