Table des matières

ToggleIntroduction

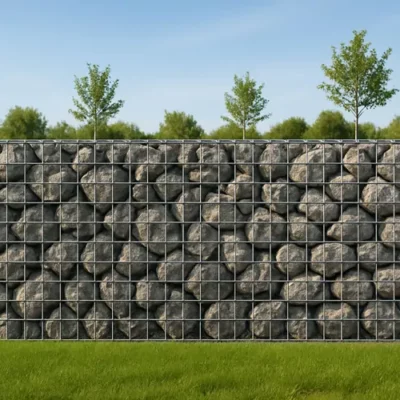

Welded wire mesh fencing has rapidly gained popularity across residential, commercial, agricultural, and industrial applications. Known for its strength, affordability, and ease of use, it offers a solid fencing solution for property owners seeking both functionality and minimal maintenance. But like any product, it comes with trade-offs.

In this comprehensive guide, we explore the real-world Pros and Cons of welded wire mesh fencing, its common types, applications, and installation tips—so you can make an informed decision.

What Is Welded Wire Mesh Fencing?

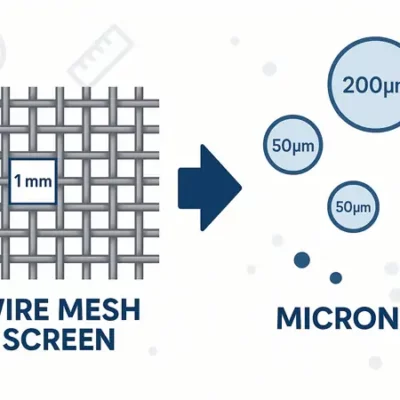

Welded wire mesh fencing is made by welding horizontal and vertical steel wires together at their intersections to form a strong, grid-like structure. It typically comes in panels or rolls and is available in various coatings like galvanized, PVC-coatedou stainless steel.

Thanks to its rigid structure, this type of fencing is ideal for applications that require strength, visibility, and low maintenance. Whether you’re enclosing a garden, securing livestock, or defining a perimeter, welded wire mesh offers a reliable solution.

Advantages of Welded Wire Mesh Fencing

1. Exceptional Strength and Durability

The welded joints provide excellent strength and resistance to deformation, making it ideal for heavy-duty applications. Unlike woven wire, welded mesh doesn’t unravel when cut, increasing its reliability.

2. Good Visibility and Airflow

The open grid structure allows for clear visibility and strong air circulation, which is essential in applications like gardens, animal enclosures, and security zones.

3. Easy Installation

Pre-fabricated panels or rolls make welded mesh fencing easier and faster to install compared to traditional wooden or masonry fences.

4. Low Maintenance

A galvanized or PVC-coated fence resists rust, corrosion, and fading, requiring minimal upkeep for years.

5. Versatile Applications

From pet enclosures to industrial boundaries, welded wire mesh adapts well to various environments.

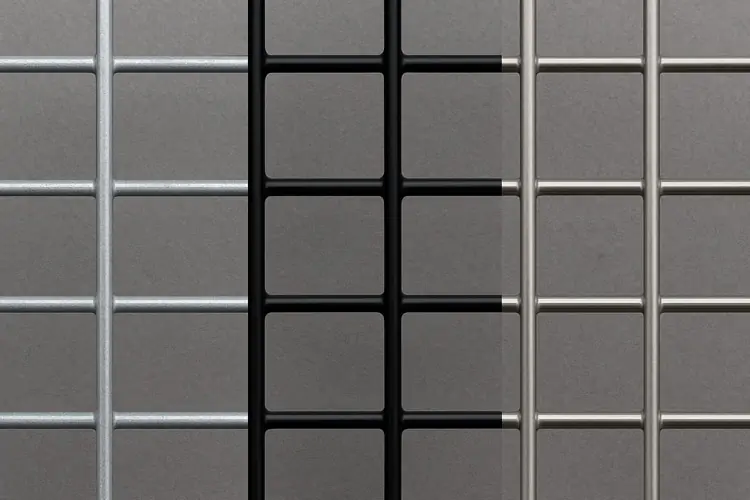

6. Aesthetic Appeal

Its clean lines and unobtrusive design fit well in both urban and rural settings. Black or green PVC-coated mesh can also blend into landscapes more naturally.

Disadvantages of Welded Wire Mesh Fencing

1. Limited Privacy

Welded mesh is transparent by design, which may not suit homeowners seeking total privacy unless additional materials like privacy slats or vegetation are added.

2. Challenging on Slopes or Uneven Terrain

Its rigid structure can make installation difficult on sloped or uneven ground, often requiring stepped or terraced layouts.

3. Vulnerability to Corrosion if Poorly Coated

If the mesh is not properly galvanized or coated, exposure to moisture can lead to rust and degradation over time.

4. Not Ideal for High-Security Scenarios

Although strong, welded mesh alone may not deter intruders unless combined with barbed wire, razor wire, or anti-climb features.

5. Difficult to Modify

Once installed, adjusting or extending the fence can be labor-intensive due to the rigid welded joints.

Types of Welded Wire Mesh Fencing

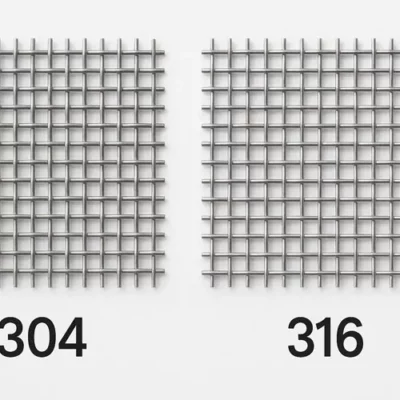

1. Galvanized Welded Mesh

Made from steel and coated with a layer of zinc, this is the most common type. It offers solid rust resistance at a low cost, ideal for outdoor use.

2. PVC-Coated Welded Mesh

Adds an extra layer of protection and aesthetic appeal. Comes in various colors like green or black and is often used in residential or garden fencing.

3. Stainless Steel Welded Mesh

The most durable and corrosion-resistant option. Used in marine, food processing, or high-end architectural applications.

4. Welded Fence Panels

These rigid panels are factory-fabricated and provide a clean, modern appearance. Best suited for permanent installations.

5. Welded Mesh Rolls

Flexible and easy to transport, these are popular for DIYers or temporary fencing.

Common Applications of Welded Wire Mesh Fencing

-

Home gardens & pet enclosures

-

Livestock and poultry pens

-

Construction site fencing

-

Factory or warehouse security

-

Public parks and schools

How to Install Welded Wire Mesh Fencing (Step-by-Step)

Step 1 – Plan and Measure Your Fence Line

Mark the corners and measure the length to determine how many posts and panels you need.

Step 2 – Set Corner and End Posts

Dig holes, add concrete, and install sturdy corner and gate posts.

Step 3 – Install Line Posts

Place intermediate posts evenly (usually 6–10 feet apart), ensuring they’re plumb.

Step 4 – Attach Mesh Panels or Rolls

Unroll or position the mesh against the posts. Secure with fencing staples, clips, or brackets.

Step 5 – Tension the Mesh

Use a fence stretcher or come-along to tighten the mesh before final fastening.

Step 6 – Install Gates (if required)

Align gates with hinges and check swing clearance.

How to Stretch a Welded Wire Fence Properly

Proper tension ensures a long-lasting, secure fence. Here’s how:

-

Use a fence stretcher tool or come-along with pulling bars

-

Start tensioning from corner posts toward the center

-

Ensure uniform pressure to prevent mesh from bowing or warping

-

Secure with clips or tension wire

FAQs – Welded Wire Mesh Fencing

Q1: How long does a welded wire mesh fence last?

Typically 10–20 years depending on coating quality and environmental exposure.

Q2: Can I install this fencing by myself?

Yes. With basic tools and some help, DIY installation is achievable.

Q3: Does it work for pets and chickens?

Absolutely. It’s often used for dogs, rabbits, chickens, and even goats.

Q4: Will it rust?

If left uncoated or exposed to harsh conditions, yes. Always choose galvanized or PVC-coated mesh.

Q5: Can it be electrified?

Yes, welded wire fencing can be used with electric fencing systems for added security.

Final Thoughts – Is Welded Wire Mesh Fencing Right for You?

Welded wire mesh fencing offers a blend of durability, versatility, and cost-effectiveness that makes it suitable for a wide range of users—from homeowners to farmers to business owners. While it’s not the best choice if privacy or high-security is your top priority, its strength, airflow, and low maintenance design make it a winner in most general applications.

Whether you need to secure a backyard, protect crops, or install a pet enclosure, welded wire mesh fencing is a solid investment—as long as you understand its pros and cons before buying.