Wire mesh products are vital components in construction, agriculture, pest control, and security applications. Among the most common types are hardware cloth e tela de arame soldada. At first glance, they may appear interchangeable—but in reality, they differ in structure, strength, applications, and cost.

In this comprehensive guide, we’ll explain everything you need to know about hardware cloth and welded wire mesh: what they are, how they’re made, their advantages, and how to choose between them.

Índice

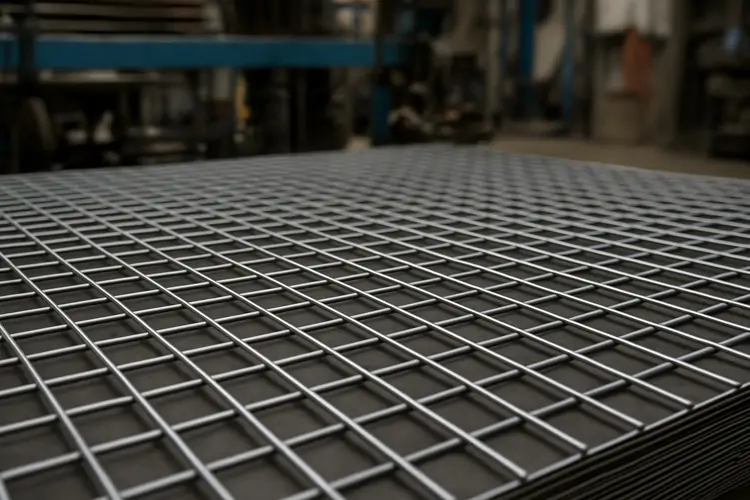

AlternarWhat Is Welded Wire Mesh?

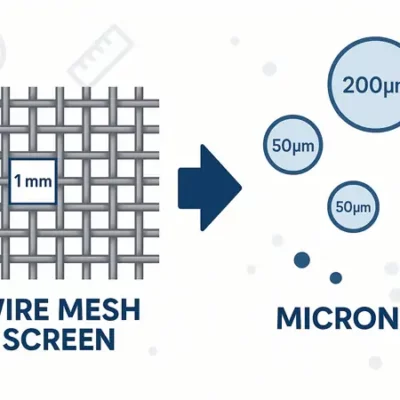

Welded wire mesh is a grid-like sheet formed by welding horizontal and vertical metal wires at their intersections. This construction provides excellent rigidity and strength.

-

Materials: Typically made from low-carbon steel wire, stainless steel, or galvanized steel.

-

Processo de fabricação: Wires are resistance-welded together at each intersection.

-

Tamanhos de malha: Common sizes include 1/2″, 1″, 2″, and larger, with wire gauges ranging from 6 to 16.

-

Formats: Available in flat panels or rolled form depending on application.

Ideal For:

-

Fencing

-

Concrete reinforcement

-

Industrial partitions

-

Animal enclosures

What Is Hardware Cloth?

Hardware cloth is a type of wire mesh with a much finer mesh pattern, usually made from thinner wire. It can be either woven or welded, though welded is more common for small mesh sizes.

-

Materials: Commonly galvanized before or after welding, and occasionally stainless steel.

-

Tamanhos de malha: Small apertures such as 1/8″, 1/4″, and 1/2″.

-

Calibre de fio: Typically 19 to 23 gauge – thinner than welded mesh.

-

Purpose: Designed more for protection and filtration than structural support.

Ideal For:

-

Rodent exclusion

-

Garden protection

-

Screen covers

-

Vent guards

Welded Wire Mesh vs. Hardware Cloth (Comparison Table)

| Recurso | Hardware Cloth | Malha de arame soldado |

|---|---|---|

| Structure | Fine mesh, thin wire | Larger mesh, thicker wire |

| Calibre de fio | 19–23 | 6–16 |

| Opening Sizes | 1/8″, 1/4″, 1/2″ | 1/2″, 1″, 2″, etc. |

| Rigidity | Flexible | Rígido e forte |

| Purpose | Pest prevention, filtering | Structural support, fencing |

| Material Options | Galvanized, stainless steel | Galvanized, PVC-coated, stainless steel |

| Custo | Less expensive per roll | More costly due to thickness |

Applications of Hardware Cloth

Hardware cloth is designed for precision and protection in delicate environments. Some common uses include:

-

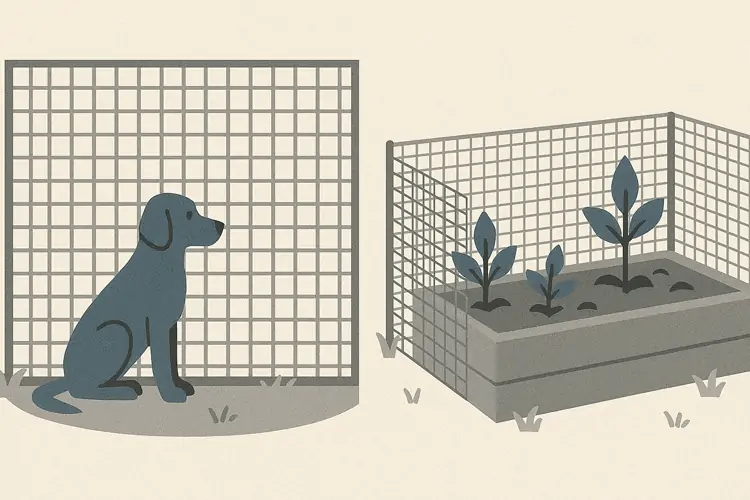

Controlo de pragas: Preventing entry of rats, squirrels, snakes, or raccoons under structures.

-

Garden Use: Lining raised beds, covering vents, and protecting crops.

-

Home Improvement: Chimney caps, attic ventilation guards, and crawl space protection.

-

Filtration or Sifting: Fine mesh used to separate small particles or insects.

Aplicações de Telas de Arame Soldadas

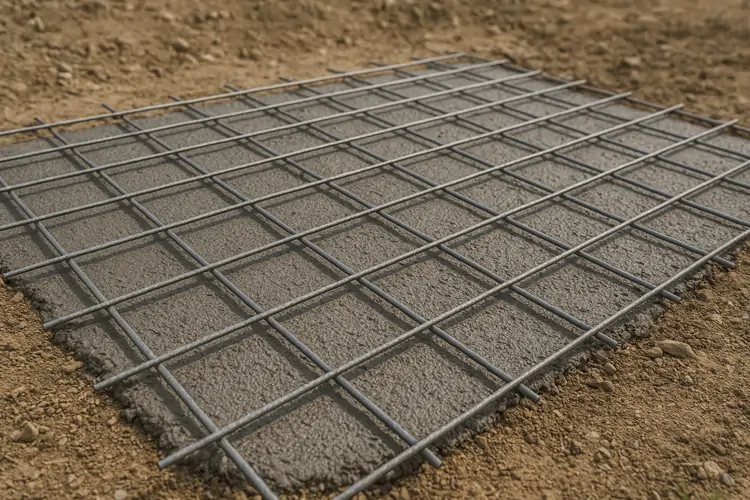

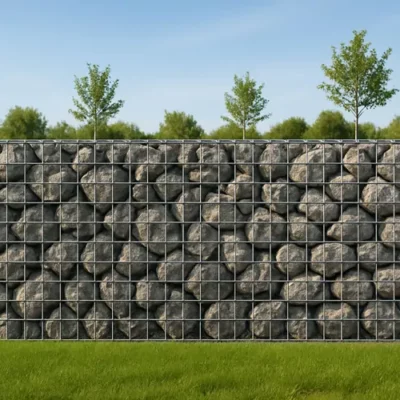

Welded mesh is more robust and designed to withstand heavier forces. It’s commonly found in:

-

Agricultura: Livestock cages, chicken coops, and animal enclosures.

-

Construção: Reinforcing concrete slabs or walls.

-

Segurança: Perimeter fencing and gates.

-

Industrial Use: Machine guards, safety panels, and warehouse partitions.

How to Choose Between Hardware Cloth and Welded Wire Mesh

When deciding between the two, consider the following:

-

Purpose: Do you need strength or small mesh openings?

-

Ambiente: Will it be exposed to moisture, soil, or chemicals?

-

Orçamento: Welded mesh is more expensive due to heavier materials.

-

Facilidade de instalação: Hardware cloth is easier to cut and bend.

-

Size and Flexibility: Smaller jobs or tight spaces may benefit from flexible hardware cloth.

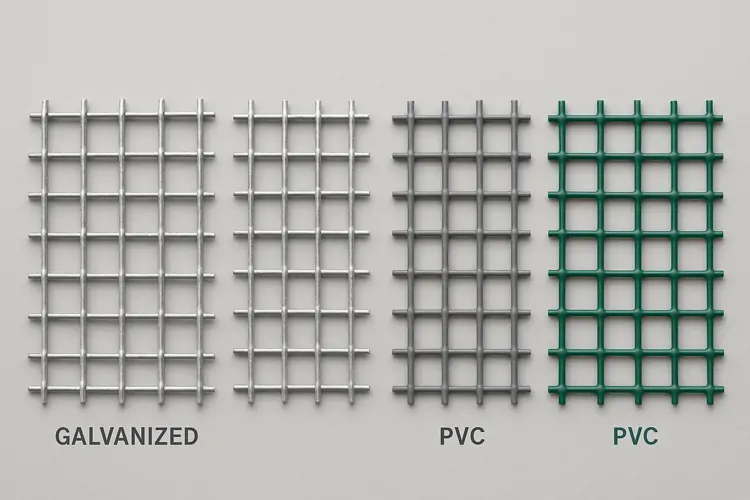

Material and Finish Options

Wire mesh performance depends heavily on material and finish.

Aço galvanizado

-

Galvanized Before Welding (GBW): Coated before welding; cheaper but weld points can rust.

-

Galvanized After Welding (GAW): Fully protected; better corrosion resistance.

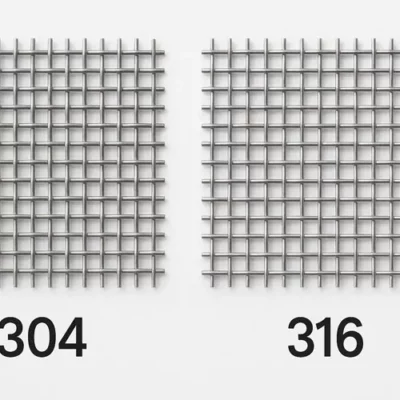

Aço inoxidável

-

Rust-proof and highly durable.

-

Ideal for marine or chemical exposure environments.

PVC-Coated Wire

-

Extra layer of protection and aesthetic finish.

-

Available in black or green coatings.

Technical Considerations

Construction & Joining

-

Welded mesh: intersections are fused for maximum strength.

-

Hardware cloth: may be welded or woven, and not as rigid.

Força

-

Welded mesh is significantly stronger, used for load-bearing applications.

-

Hardware cloth bends more easily and is suitable for light-duty uses.

Opening Size Matters

-

Smaller mesh excludes insects and rodents.

-

Larger mesh allows airflow and is easier to clean.

Will Wire Mesh Unravel?

-

Welded mesh will not unravel.

-

Woven hardware cloth may unravel if cut improperly.

What Is “Coil Memory”?

-

Refers to the tendency of wire mesh to stay curled after being unrolled.

-

Common in hardware cloth rolls; can be flattened manually.

Our Wire Mesh Options

(For company use only – optional section)

We supply both welded wire mesh and hardware cloth in the following materials:

-

Galvanized Before Weld

-

Galvanized After Weld

-

Stainless Steel 304/316

-

Black Annealed Wire Mesh

-

PVC-Coated Wire Mesh

Available in:

-

Mesh sizes from 1/8” to 4”

-

Wire gauges from 23 to 6

-

Roll widths from 24” to 72”

-

Custom cut panels available upon request

Summary

Hardware cloth and welded wire mesh serve different but equally important purposes. Choosing the right mesh depends on:

-

Mesh size required

-

Level of strength needed

-

Environmental conditions

-

Material preferences

-

Orçamento

Use hardware cloth for fine control and pest exclusion. Choose welded mesh for structural integrity and long-term durability.

FAQs

Q1: Is hardware cloth the same as welded wire mesh?

No. While hardware cloth is sometimes welded, it uses finer wire and smaller mesh openings than standard welded mesh.

Q2: Which is stronger—hardware cloth or welded wire mesh?

Welded wire mesh is stronger due to thicker wire and rigid welding at intersections.

Q3: Will wire mesh rust?

Galvanized or stainless steel options are rust-resistant. Galvanized After Weld is the most rust-proof among economical choices.

Q4: What size mesh keeps out rats or snakes?

1/4” or smaller hardware cloth is recommended for rodents and snakes.

Q5: Can I use hardware cloth for fencing?

Only for light-duty fencing like gardens or pest control. For strength and durability, welded mesh is better suited.