Learn everything about wire mesh filters — how they work, key benefits, types, applications, pricing, and expert tips for choosing the right one.

Wire mesh filters are indispensable tools across industries where precision filtration, durability, and reliability are paramount. From purifying liquids and gases to protecting machinery from contaminants, wire mesh filters deliver high performance in demanding environments. This guide will take you through everything you need to know about wire mesh filters — how they work, where they’re used, and how to choose the right one for your application.

Table of Contents

ToggleIntroduction to Wire Mesh and Filtration

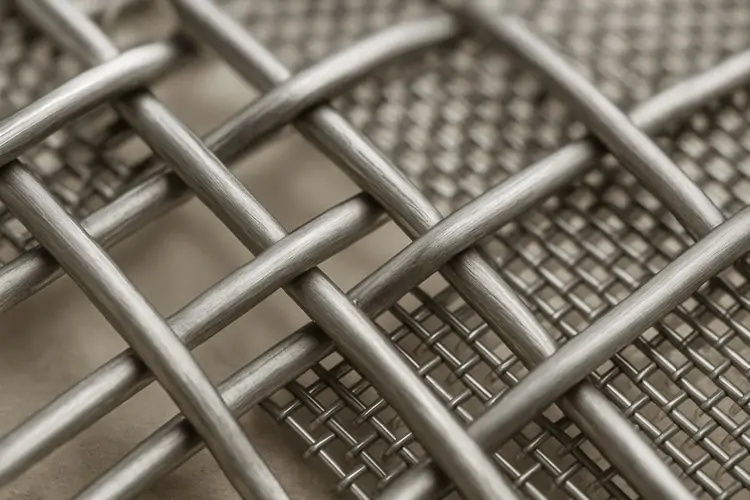

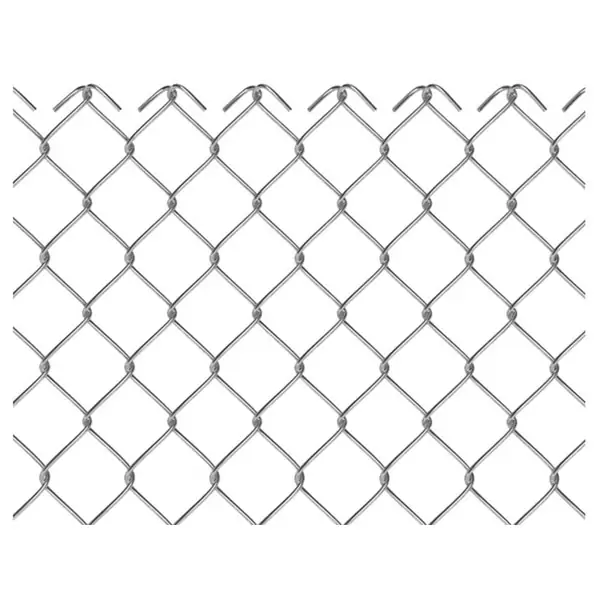

Wire mesh refers to a grid of intersecting wires, typically made from metals like stainless steel, brass, or galvanized steel. These meshes can be woven or welded, forming a porous surface that’s ideal for mechanical filtration.

Wire mesh filters are components that utilize wire mesh as the core medium to separate solids from fluids or gases. Their simplicity, strength, and reusability make them a preferred choice in industries ranging from chemical processing to food production.

How Does a Wire Mesh Filter Work?

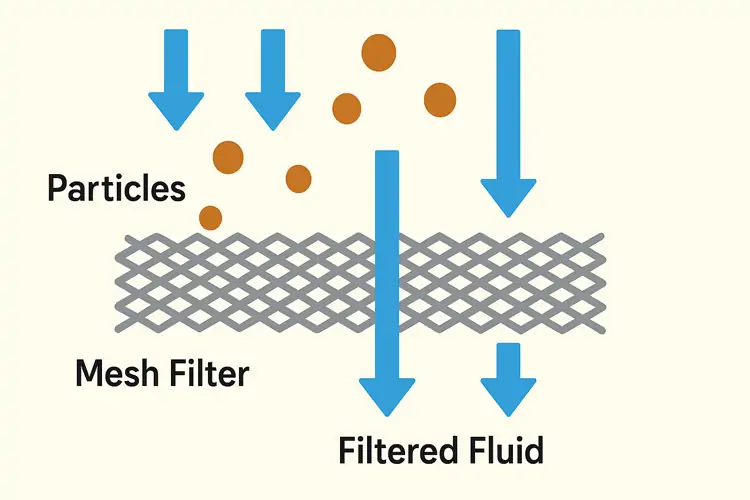

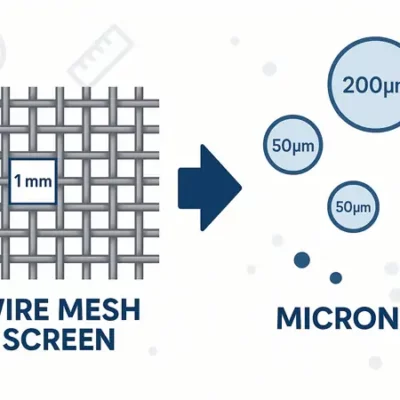

Wire mesh filters perform mechanical filtration. As fluid or air passes through the mesh, particles larger than the mesh openings are trapped while the rest flows through. Mesh opening size — often expressed in microns — determines the filter’s efficiency.

Different types of wire mesh filters include:

-

Single-layer mesh for basic filtering

-

Multi-layer or sintered mesh for high-pressure systems

-

Pleated mesh for larger surface area in compact space

Key Benefits of Wire Mesh Filters

✅ High Durability

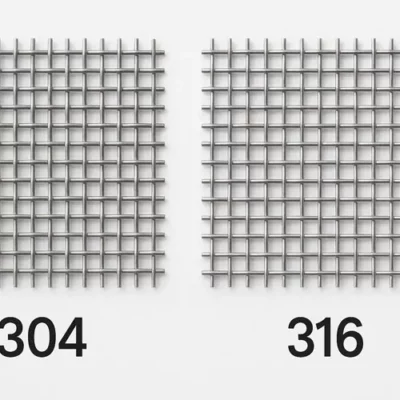

Wire mesh filters withstand high temperatures and pressures, especially stainless steel variants like 304 and 316.

✅ Reusability

Unlike disposable filters, they can be cleaned and reused multiple times.

✅ Precision Control

Customizable mesh sizes allow micron-level control of particle retention.

✅ Environmentally Friendly

Less waste and longer lifespan reduce environmental impact.

Limitations of Wire Mesh Filters

-

Not suitable for ultrafine filtration (<5 microns)

-

Can clog quickly without pre-filtration

-

May require regular maintenance in dusty or viscous environments

Wire Mesh Filter Types and Shapes

Wire mesh filters come in various shapes and configurations:

-

Disc filters (flat, circular)

-

Cylindrical filters (tube-like for pipes)

-

Cone filters (used in nozzles or funnels)

-

Basket filters (for bulk solids separation)

Applications of Wire Mesh Filters

Wire mesh filters serve in diverse sectors:

🏭 Industrial Processing

-

Petrochemical and chemical separation

-

Powder processing

🚗 Automotive & Aerospace

-

Fuel, oil, and air filtration in engines and turbines

🧪 Pharmaceuticals & Labs

-

Sterile filtering of air and fluids

💧 Water Treatment

-

Sand, sediment, and rust removal

🥫 Food & Beverage

-

Filtration of syrups, sauces, and dairy products

🌬️ HVAC Systems

-

Dust and debris control in ventilation systems

Filter Cloth vs. Wire Mesh: What’s the Difference?

| Feature | Filter Cloth | Wire Mesh Filter |

|---|---|---|

| Material | Synthetic or metal | Primarily metal |

| Filtration fineness | Higher (sub-micron) | Micron level (10–2000μm) |

| Durability | Lower | Higher |

| Reusability | Often disposable | Reusable |

How to Choose the Right Wire Mesh Filter

Consider the following specifications:

-

Outer diameter – size must match housing

-

Height – affects filter capacity

-

Dimensão da malha – controls particle retention (e.g. 50 mesh ≈ 300 microns)

-

Mesh material – stainless steel, brass, galvanized

-

Wire diameter – impacts flow rate and strength

-

End cap or ring construction – materials and sealing methods

How Much Do Wire Mesh Filters Cost?

Prices vary based on:

-

Material (SS316 > SS304 > Galvanized)

-

Size and complexity

-

Custom fabrication needs

Typical cost range:

-

Standard discs: $2–$10

-

Cone filters: $10–$30

-

Custom filters: $30–$100+

Maintenance and Cleaning Tips

-

Backflushing: Reverse-flow cleaning

-

Ultrasonic cleaning: High-frequency waves remove residue

-

Soaking in solvent or detergent: For oily or sticky substances

-

Replace filters if you notice:

-

Deformation

-

Permanent clogging

-

Rust or corrosion

-

FAQs

Q1: Can wire mesh filters be used with high-temperature fluids?

Yes. Stainless steel filters can withstand temperatures over 800°C.

Q2: What is the difference between mesh and micron?

Mesh refers to openings per inch; micron is the particle size it can filter. (E.g., 100 mesh ≈ 150 microns)

Q3: Can I reuse a wire mesh filter?

Yes — it can be cleaned and reused many times.

Conclusion

Wire mesh filters are essential components in industrial and commercial systems that demand strength, precision, and reliability. They offer long-term savings, easy maintenance, and versatility across countless applications. Whether you’re filtering fuel, air, or fluids, selecting the right mesh filter will boost system performance and protect valuable equipment.