Steel Grating Suppliers from China

Steel grating introduction to help you better understand it

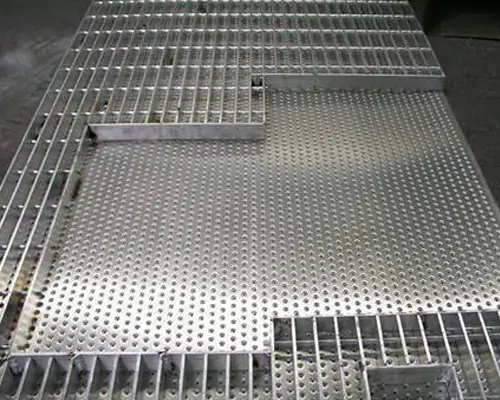

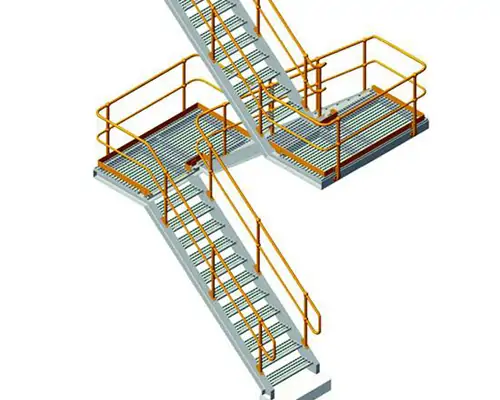

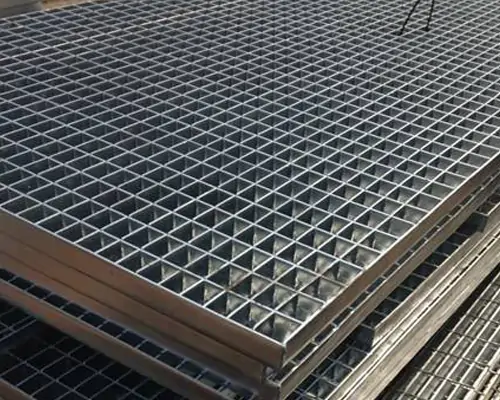

Steel grating, also known as bar grating or metal grating, is an open grid assembly of metal bars, in which the bearing bars, running in one direction, are spaced by rigid attachment to cross bars running perpendicular to them or by bent connecting bars extending between them, which is designed to hold heavy loads with minimal weight. It is widely used as floors, mezzanines, stair treads, fencing, trench covers and maintenance platforms in factories, workshops, motor rooms, trolley channels, heavy loading areas, boiler equipment and heavy equipment areas, etc.

Hagamos un recorrido

- High strength and firm structure.

- High anti-slip performance.

- High load capacity and resistance to deformation.

- Anti-press.

- Explosion proof.

- Light weight.

- Various styles and sizes for choice.

- Good ventilation and heat resistance.

- Alkali and acid resistance.

- Harsh environment resistance.

- Corrosion and rust resistance.

- Easy installation.

- Durable and long service life.

- MaterialCarbon steel, aluminum steel, stainless steel.

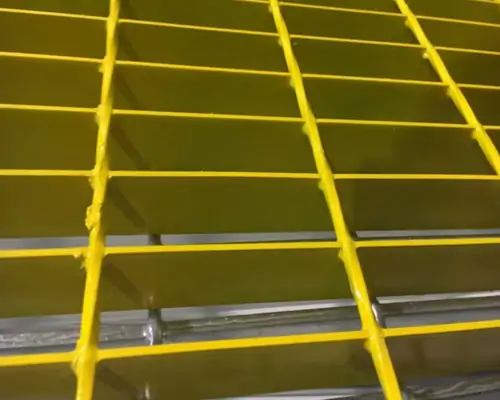

- Tratamiento de superficiesGalvanized, mill finished, painted, powder coated, PVC coated.

- Surface typeStandard plain surface, serrated surface.

- Common bearing bar spacing7/16″, 1/2″, 11/16″, 15/16″, 19/16″ in 1/16″ increments.

- Common cross bar spacing2″, 4″ in 1″ increment.

- Bearing bar depth3/4″ to 7″.

- Bearing bar thickness1/8″ to 1/2″.

Type of anchorage

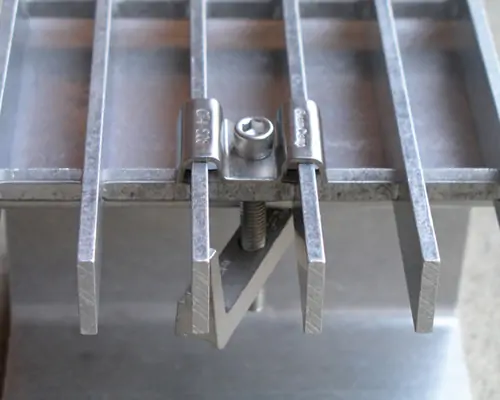

A special bent-clip type fastener for removable bar grating panels.Bent clips bridging two bearing bars are available in galvanized steel, stainless steel, or aluminum.

Mechanical fasteners installed from the top surface of the grating create a friction connection with the flange supporting the panel.“G” clips are easily installed without drilling or welding.

Grating can be connected by one man only, working from above, without the need to drill the steel or weld on site.

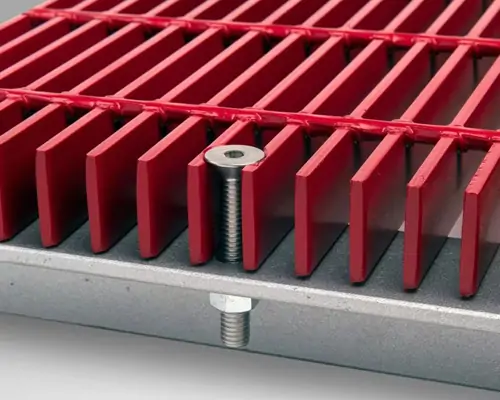

Plates, punched with holes and welded between the bearing bars, facilitate bolting to the supporting structure.

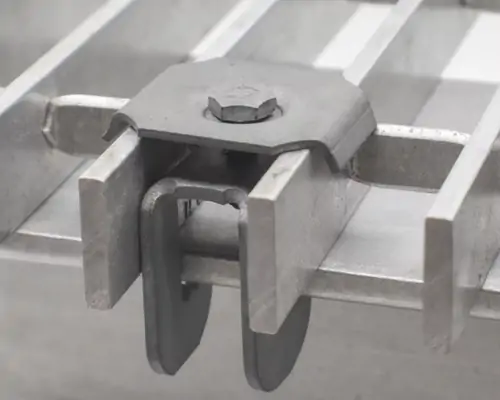

Narrow formed clip captures one bearing bar when spacing is limited, They are especially helpful in holding down riveted grating.

The narrow spacing of close mesh grating allows for countersinking or milling of the bearing bars to support bolt shoulders. It is available for aluminum grating only.

Aplicaciones

Stair tread.

Floor.

Sun visor.

Tree cover.

Bridge construction.

Chair.

Baby carriage.

Food panel.

Walkway.

Showcase ground.

Fountain panel.

Trench cover.

Decorative wall.

Shelve.

Substation fire pit.

Optional platform.

Ceiling.

Ramp.

Drainage cover.

Security fence.

Stand.

Clean area panel.

Catwalk stage.

Window.

Lifting track.

Industrial truck.

Transformer reservoir.

Observation tower.

Split obstacle or screen.

Raw Material

Galvanized steel Grating

It has great corrosion-resistant, shiny surface appearance and good ventilation and is widely used in the petrochemical industry, power plants and sewage treatment plants.

Painted Steel Bar Grating

It comes in a variety of colors, which can be selected to match the device according to your needs.

Stainless Steel Grating

It has the most excellent corrosive resistant among all steel gratings and is especially suitable for various strong corrosive environments.

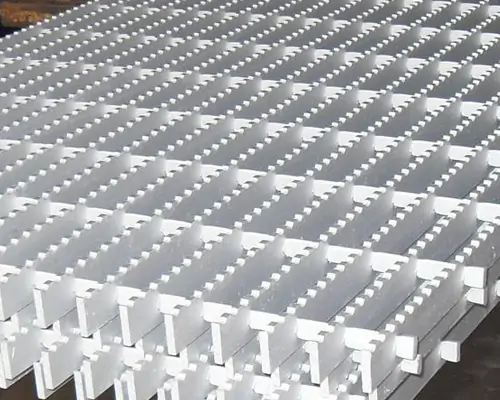

Aluminum Grating

It is lighter in weight without compromising to the load capacity and mechanical strength and is mainly used for platform ceilings and outdoor curtain walls.

Manufacturing Process

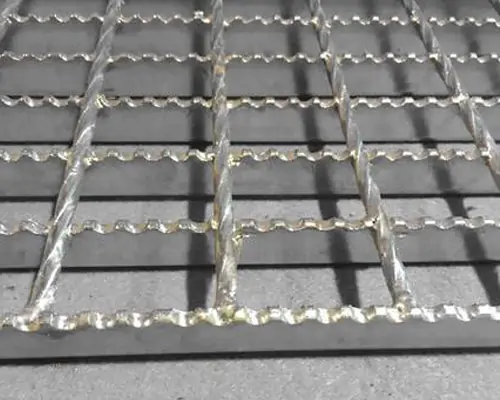

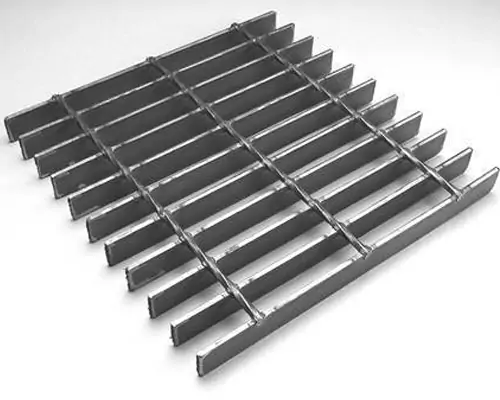

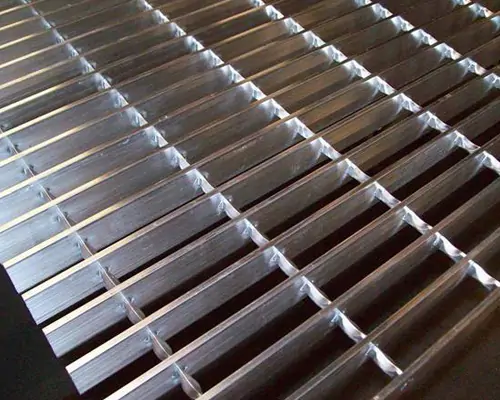

Welded Steel Grating

It consists of bearing bars that are automatically resistance-welded with the cross bars via precise use of intense heat and pressure.

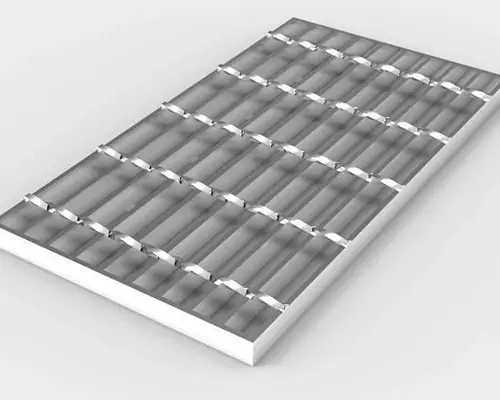

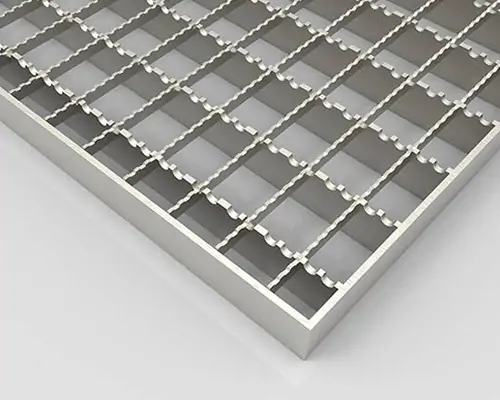

Press-locked Steel Grating

It relies on employing enormous hydraulic pressure that fuses the two close-tolerance slotted bars together.

Swage-Locked Grating

It is manufactured by inserting cross bars into pre-punched holes in the bearing bar and then cross bars are swaged forming a positive mechanical connection.

Riveted Grating

It has high load capacity, anti-slip surface to be used in heavy traffics as platforms, walkways as well as bride decking.

Bearing Bar

Flat bar steel grating

It is one of the most popular and versatile industrial steel gratings.

I Bar Steel Gratings

It provides light weight yet high strength and load capacity.

Louver Steel Grating

It is widely used in outdoors, such as:sunshade and building facade.

Surface

Plain steel grating

It provides excellent bearing capacity and is widely used in almost all industrial applications.

Serrated steel grating

It provides excellent slip resistance and is especially applicable to places where excellent slip resistance is required.

Load

Standard Steel Grating

It is easily fabricated and provides a high load structure and is widely used as steel grating platform, walkway, bridge decking and flooring.

Heavy Duty Steel Grating

It supplies far greater strength-to-weight ratio than other flooring materials to bear the heavy load such as forklift or truck traffic.

Dense Steel Grating

It has closer bearing bar spacing less than 25 mm. It is mainly used in the occasion have higher request for gratings.

Others

Irregular Steel Grating

Compound steel Grating

Steel Grating Accessories

Grating Stanchion Railing Ball Joint Handrail

Serrated Welded Steel Grating

Serrated Press-Locked Steel Grating

Plug Grating

Nuestras ventajas

YESON, nos dedicamos a la exportación de barandillas desde hace más de 15 años. Nuestra fábrica cuenta con avanzados equipos de producción, trabajadores técnicos cualificados y un completo departamento de diseño y pruebas. Nuestros productos de barandillas se han exportado a más de 70 países. Nuestra fábrica cuenta con un amplio inventario de materias primas para facilitar una producción y entrega rápidas. Proporcionamos a nuestros clientes productos de barandillas de alta calidad y precios competitivos, ayudando cada vez a más clientes a explorar el mercado local, y nuestras ventas crecen rápidamente cada año.

PREGUNTAS FRECUENTES

P1: ¿Son ustedes una fábrica de verdad? ¿O una empresa comercial?

R: Sí, hemos estado en el suministro de los productos en este campo para 20 + years.We tienen tanto la fábrica real (Anping Yeson Wire Mesh Products Co., Ltd) y la empresa comercial (Hebei YESON International Trade Co., Ltd), principalmente producir y vender productos de malla de metal.

P2: ¿Puedo tener una muestra para comprobarlo primero?

R: Sí, ofrecemos muestras de materias primas o pequeños pedidos de muestras para que las compruebe. Apenas diga a nuestros especialistas de los detalles y le ayudarán sobre él.

P3: ¿Puedo venir a China para la inspección en fábrica?

R: Por supuesto, le invitamos a visitar nuestra fábrica y oficinas. Ahora también apoyamos usando ZOOM o WeChat para la inspección en línea de la fábrica.

P4: ¿Pueden diseñar y fabricar a petición del cliente?

R: Respaldamos los requisitos de personalización de los clientes y proporcionamos las soluciones y servicios correspondientes.

P5: ¿Puedo obtener un precio más bajo si hago un pedido grande?

R: Por supuesto, precio más barato con pedido grande.

P6: Si la calidad no se ajusta a lo que pido, ¿cómo solucionan este problema?

R: En primer lugar, no permitimos que ningún producto defectuoso salga de nuestra fábrica, realizamos una estricta inspección de calidad en cada paso. Pero si hay cualquier problema, garantizaremos para solucionarlo en el plazo de 2 días laborables después de sus imágenes o prueba de los vídeos.

P7: ¿Tienen garantía de calidad?

P8: ¿Cómo se envía la mercancía?

ALe cotizaremos el flete marítimo, si la mercancía no es grande, se cargará por flete aéreo o Express. No importa cualquier forma de transporte, nuestros transitarios proporcionarán un servicio profesional para asegurar que las mercancías lleguen a su lugar sin problemas.

P9: ¿Cuál es su política de muestras?

R: Podemos suministrar la muestra si tenemos piezas listas en stock, pero los clientes tienen que pagar el coste de mensajería. Y todo el coste de la muestra será consolidado después de que usted ponga la orden.

Pida presupuesto hoy mismo

Eche un vistazo a cómo perciben nuestros productos y servicios algunos de nuestros clientes:

Productos relacionados

-

Product Name: Press-Welded Steel Grating Size: Customizable Length: 3000mm Thickness: 0.12mm - 1.50mm Cross Bar Pitch: 50mm - 100mm Material: Galvanized Sheet, Stainless Steel Place of Origin: Anping, Hebei, China....

-

Product Name: Press Lock Steel Grating Size: Customizable Length: 3000mm Thickness: 0.12mm - 1.50mm Cross Bar Pitch: 50mm - 100mm Material: Galvanized Sheet, Stainless Steel Place of Origin: Anping, Hebei,...